Cut-Mor Integrated Measuring Device™

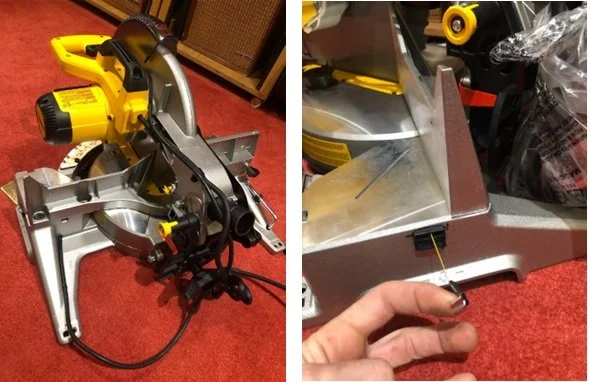

This prospectus will introduce the Cut-Mor Integrated Measuring Device™, a newly patented technology available for licensing. The design of the Cut-Mor Integrated Measuring Device™ makes it easy to support accurate and efficient cutting in a single process and simplifies tasks for professionals and DIY users.

The Cut-Mor Integrated Measuring Device™ is guided by a precise, elongated band that is stored within a compact, durable shell. It securely engages with the leading edge of the material to be measured. As material advances, sensors capture real-time measurement data. The data is then converted within a small processor to provide a precise measurement on an easy to read LED display.

The Cut-Mor Integrated Measuring Device™ is perfect for job-site construction or home projects and reduces labor hours, material waste, and cutting errors. With an all-in-one functionality, the device provides control and a rapid cutting process. By incorporating this device, the need to measure material separately is eliminated.

PRODUCT FEATURES & BENEFITS

Special features

Integrated measuring system ideal for portable tool applications

Retractable elongate band

Digital measurement display

Length acquisition sensors (rotary-based and/or optical)

User input interface (touchscreen or buttons)

Limitless tool applications

Lightweight, durable construction

Modular mounting options

Battery or tool-powered

Visual and audio alerts

Calibration functionality

Multi-unit measurement display (in/cm/mm)

PRODUCT DETAILS

The Cut-Mor Integrated Measuring Device™ is a precise solution built to streamline the measuring and cutting process. It consists of an elongated band, like a tape measure, housed inside a compact band housing. The band itself would be made from a durable, non-stretch material, reinforced polymer, or flexible metal, to maintain integrity and accuracy over time. It operates under tension and includes end-mounted catches designed to grip onto the edge of the material, allowing the band to extend securely and precisely from the housing..

The sensor system makes the Cut-Mor Integrated Measuring Device™ unique and includes one or more rotary encoders to detect how far the band has extended. These encoders feed the length data into the computing unit to calculate the exact length from a fixed cutting point to the catch. The measurements are then displayed on a digital interface to allow users to read the measurements instantly and adjust as needed for perfect cuts.

The Cut-Mor Integrated Measuring Device™ is constructed from high-strength, industrial-grade aluminum and reinforced polymer components, offering a balance of durability, precision, and lightweight handling. It can be mounted on either side of the tool, depending on preference. The Cut-Mor Integrated Measuring Device™ is designed for both retrofit and built-in applications, making it an accurate and easy to use device.

Materials needed to produce the Cut-Mor Integrated Measuring Device™:

Stainless steel

Reinforced nylon

Fiberglass

Polycarbonate

ABS plastic

Aluminum

Steel

Rubber

Zinc alloy

Spring steel

Carbon steel

ARM microcontroller

Printed circuit board (PCB)

Lithium-ion battery

Touchscreen LCD

LED display

Silicone (for buttons)

Industrial epoxy

Foam or rubber gaskets

Neodymium magnets

Optical or laser sensors

Glass (for display screens)

Copper (for wiring and circuits)

The Cut-Mor Integrated Measuring Device™ can elevate your product portfolio to new heights. We are seeking a long-term arrangement with a company to manufacture, market, and/or distribute this new technology based on the acquisition of the intellectual property rights . Contact us below

Contact Us

Our VP of Business Development, Amy Schleicher, is ready to answer any questions you may have.

Phone: 913-201-8025

E-mail: Amy@bankonip.com

Patent Information

Patent 12,228,394

Inventor Highlight

Chris Fisher was born in Ohio, where the Fisher family’s legacy began in the 1800s with a proud tradition of wood and steel craftsmanship, most notably producing and selling the iconic Fisher automobile bodies. Raised in upstate New York, where he still resides, Chris began his career in 1986 at a local lumber yard. He soon transitioned into general contracting to help fund his college education and pursue a music career. Over the years, he has worked with some of the most creative and successful individuals across industries and continues to bring that same passion and craftsmanship to his work today.

Social Media

Follow us in real time! Stay connected.

“Give me six hours to chop down a tree and I will spend the first four sharpening the axe.”