Duct Master Support Tool

HVAC systems function as the respiratory system of a building—when thoughtfully designed and well-maintained, they play a vital role in enhancing indoor air quality (IAQ). Through effective filtration, ventilation, humidity regulation, and strategic zoning, HVAC systems can create healthier, more comfortable environments. However, when neglected or poorly configured, they can become sources of airborne contaminants. Common issues such as insufficient ventilation, imbalanced airflow, and improper humidity levels—combined with a lack of maintenance—can lead to the buildup of dust, mold, and bacteria.

Installing HVAC ductwork presents its own set of challenges. The difficulty varies widely depending on the system’s complexity, the architectural layout, and the installer’s expertise. Properly hanging and securing ducts is labor-intensive and typically requires a minimum of two skilled workers, which adds to both the time and cost of installation.

The U.S. HVAC services market is projected to reach $28.2 billion in 2025, growing to $38.8 billion by 2030 (mordorintelligence.com), driven by retrofits, new construction, and energy-efficiency incentives. Within this market, ductwork installation remains a significant cost center, with average project costs ranging from $2,000 to $7,500, and labor rates estimated at between $50 to $150 per hour, depending on complexity and site conditions (angi.com).

The Duct Master Support Tool™ introduces a scalable duct support device that directly addresses this cost burden. By reducing labor dependency and improving installation precision, it offers a compelling pathway to lower overhead and increase efficiency.

PRODUCT FEATURES & BENEFITS

Special features

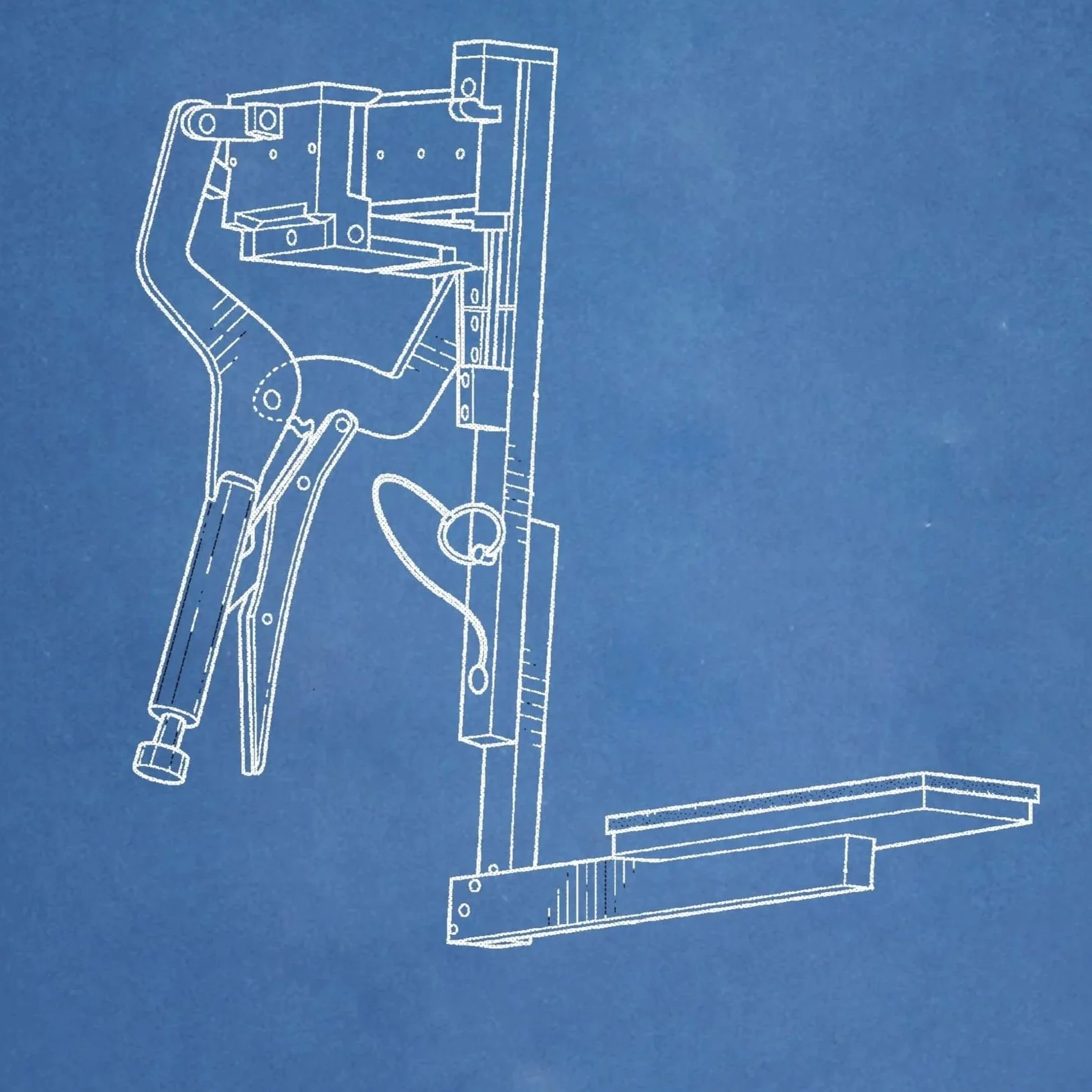

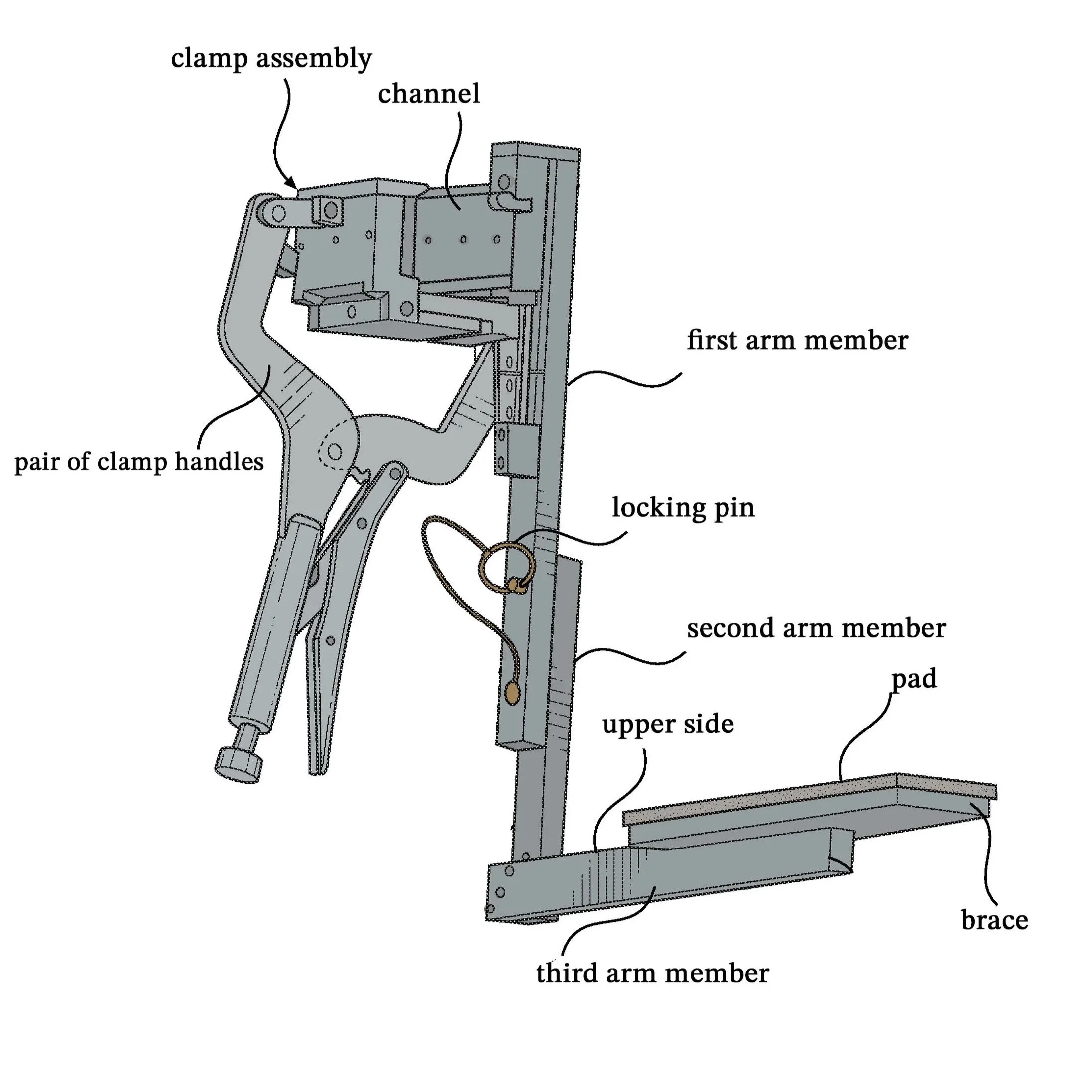

Adjustable clamp assembly

Multi-arm support structure

Integrated longitudinal brace - prevents sagging or deformation of the duct during installation

Single-operator operability – reducing labor costs and scheduling constraints

Versatile application – compatible with both rigid and flexible duct types

Modular design allows for rapid deployment and repositioning, streamlining installation

Improved safety and ergonomics - by stabilizing the duct mechanically, reducing the need for installers to hold heavy components overhead, lowering the risk of strain or injury

PRODUCT DETAILS

The Duct Master Support Tool™ introduces a novel duct support device engineered to streamline HVAC ductwork installation. This innovation directly addresses one of the most labor-intensive and risk-prone aspects of HVAC deployment: securing and stabilizing ductwork during installation. By reducing manpower requirements and improving installation precision, the Duct Master Support Tool™ offers compelling advantages in cost-efficiency, safety, and scalability. The Duct Master Support Tool™ would be available in two designs: a Hot Air Bracket and a Cold Air Bracket.

The Duct Master Support Tool™ features a multi-arm support assembly with adjustable clamp mechanisms designed to affix securely to joists or other structural elements.

Key components include:

• Adjustable clamp assembly with dual handles for rapid, secure attachment to joists or other support structures

• Articulated arm system enabling precise positioning and stabilization of ductwork

o First Arm Member: Affixed to the clamp assembly; acts as the primary extension

o Second Arm Member: Pivotally connected to the first arm, enabling angular adjustment.

o Third Arm Member: Perpendicularly affixed to the second arm; supports the duct horizontally.

o Fourth Arm Member (optional): Forms a U-shaped configuration with the third arm for enhanced load distribution and balance.

• Integrated brace along the third arm member to maintain longitudinal support and prevent sagging and deformation

• Optional fourth arm forming a U-shaped configuration for enhanced load

distribution and balance

This configuration allows a single technician to stabilize and install ductwork that would traditionally require a team, mitigating installation delays and reducing labor costs.

Materials needed to produce the Duct Master Support Tool™:

Clamp assembly

o Steel or aluminum alloy

o Clamp handles

o Spring or screw mechanism for width adjustment

Arm assembly

o Lightweight metal tubing – aluminum or steel

o Pivot joints or hinge mechanisms

o Locking brackets or detents for angular positioning

Longitudinal brace

o Reinforced aluminum

Fasteners and connectors

o Bolts, nuts, washers

o Optional quick release pins or locking collars

Optional padding or coating

o Rubber or silicone pads at contact points to prevent

damage to ductwork

o Powder coating or anodizing for surface protection

The Duct Master Support Tool™ can elevate your product portfolio for success. We are seeking a long-term arrangement with a company to manufacture, market, and/or distribute this new technology based on the acquisition of the intellectual property rights . Contact us below

Contact Us

Our VP of Business Development, Amy Schleicher, is ready to answer any questions you may have.

Phone: 913-201-8025

E-mail: Amy@bankonip.com

Patent Information

Patent #12,173,921

Inventor Highlight

Mr. Jeffrey Faber holds United States Utility Patent No. 12,173,921 B2 filed on October 6, 2021 and issued on December 24, 2024. This patent for the Duct Support Device expires in 2044, commensurate with the filing date. This patent has 15 claims that protect the exclusive function of the Duct Master Support Tool™. Mary’s dedication extends beyond bedside care. She is committed to mentoring junior nurses, promoting best practices in critical care, and staying abreast of the latest advancements in cardiac and ICU treatment protocols. Her combination of clinical excellence, leadership, and patient advocacy has earned her the respect of colleagues, physicians, and patients alike.

Known for her meticulous attention to detail and unwavering commitment to patient safety, Mary Elliott continues to make a meaningful impact in critical care nursing, setting a high standard for excellence.

Social Media

Follow us in real time! Stay connected.

“Wherever the art of Medicine is loved, there is also a love of Humanity.”