EZ- MAG

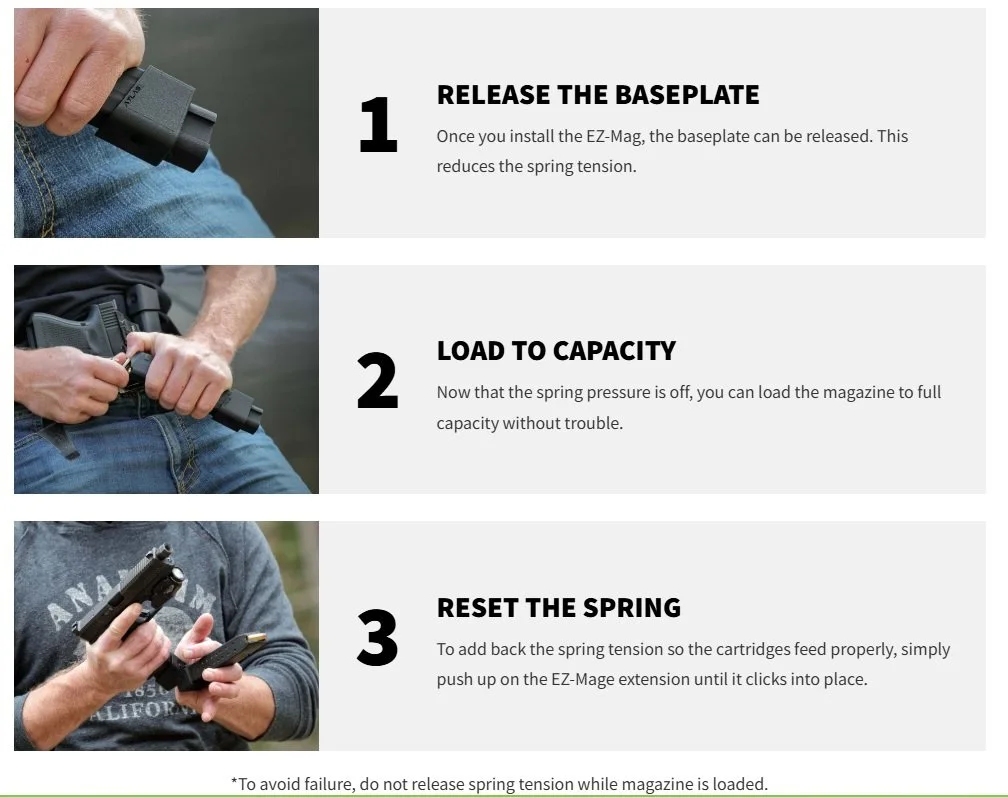

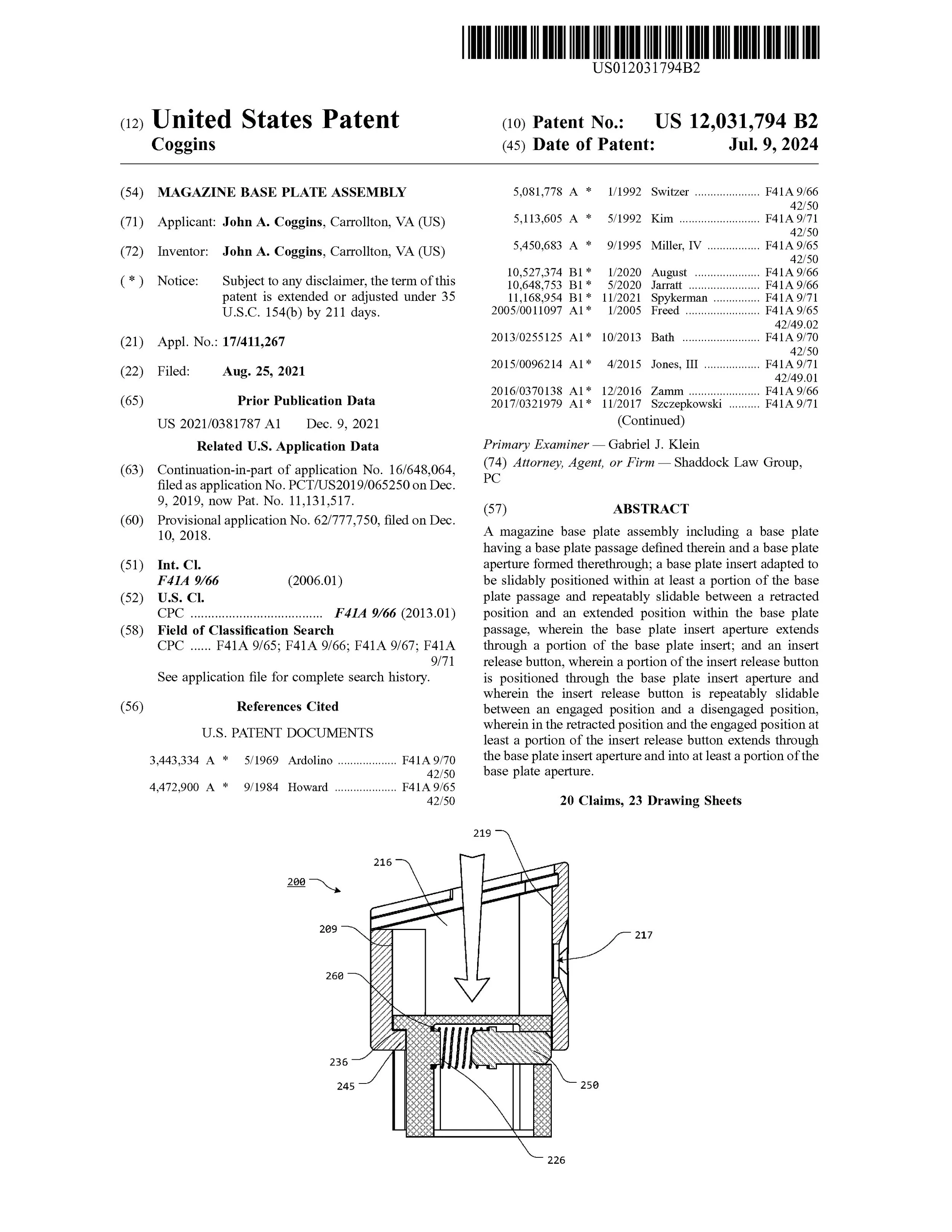

The EZ-MAG is a cutting-edge magazine base plate assembly engineered to provide enhanced functionality, effortless usability, and unmatched reliability. Designed with precision, the base plate serves as the foundation of the system, incorporating a base plate passage and a base plate aperture to house its innovative sliding mechanism.

This structural design ensures durability and efficiency, allowing for a streamlined and intuitive user experience. Whether used in high-stress environments or for recreational applications, the EZ-MAG offers a seamless solution for magazine adjustments.

Within the EZ-MAG system is the base plate insert, which is meticulously crafted to fit securely within the base plate passage. This insert is designed to glide smoothly between a retracted and extended position, enabling users to make quick modifications without compromising stability.

PRODUCT FEATURES & BENEFITS

Special features

Spring tension relief

Faster and easier reloading

Permanent attachment to magazine

PRODUCT DETAILS

The EZ-MAG features a precision-engineered base plate that serves as the foundation of the assembly. Designed for durability and long-term reliability, the base plate includes a base plate passage and aperture that allow for seamless interaction with the sliding insert. These elements ensure a secure and stable fit while enabling smooth transitions between positions. The robust construction of the base plate ensures it can withstand repeated use in various conditions, making it a dependable choice for professionals and enthusiasts alike.

At the core of the EZ-MAG is its base plate insert, which is designed to move effortlessly within the base plate passage. This slidable insert transitions between retracted and extended positions, allowing users to modify their magazine configuration with ease. Whether adjusting for storage, reloading, or maintenance, the EZ-MAG provides a streamlined and efficient mechanism that enhances overall firearm handling. The smooth movement of the insert ensures that adjustments can be made quickly and without unnecessary resistance.

Materials needed to produce the EZ-MAG:

Baseplate

Spring release/reset button

Connection hardware

The back consists of a similar combination of boards or sheets, irons, and bolts, with a grill replacing some of the boards in the upper part. Each deck support is fastened to a back support using two heavy steel braces bolted to the supports. All of the angle irons and braces are powder coated, all of the wooden boards are pressure treated, and all of the fasteners and the grill are galvanized.

A major opportunity is for future potential product lines to integrate the EZ-MAG system with a magazine extension, creating a versatile two-in-one product that delivers enhanced functionality and added value. Central to the EZ-MAG’s intuitive operation is a spring-loaded release/reset button, which serves as a repeatable locking mechanism. This button engages through the base plate insert aperture, locking the insert securely in place during use. When pressed, the spring mechanism allows for smooth disengagement, enabling users to slide or adjust the insert quickly and reliably. This design ensures both secure retention and effortless reconfiguration. Constructed from high-quality materials and engineered with ergonomic precision, the integrated EZ-MAG and magazine extension system offers a durable, performance-driven solution for users seeking improved control, customization, and efficiency in magazine handling.

The EZ-MAG can help load your product portfolio for success. We are seeking a long-term arrangement with a company to manufacture, market, and/or distribute this new technology based on the acquisition of the intellectual property rights . Contact us below

Contact Us

Our VP of Business Development, Amy Schleicher, is ready to answer any questions you may have.

Phone: 913-201-8025

E-mail: Amy@bankonip.com

Patent Information

Patent 12,031,794

Inventor Highlight

John Coggins is a highly skilled mechanical engineer specializing in defense technology and advanced systems development. With a deep understanding of mechanical design, materials science, and precision engineering, he plays a critical role in developing cutting-edge defense solutions that enhance national security and operational effectiveness.

With years of experience in the defense industry, John has contributed to the design, testing, and optimization of complex mechanical systems used in military applications. His expertise spans a range of areas. He is proficient in computational modeling, finite element analysis (FEA), and advanced manufacturing techniques that ensure the highest standards of reliability and performance.

Social Media

Follow us in real time! Stay connected.

“A free people ought not only to be armed, but disciplined...”