Modular Contaminate Capture and Sterilization

In our globally connected world, the ease of travel and exchange has helped spread ideas, cultures, and technologies. But it has also amplified vulnerabilities—none more evident than during the COVID-19 pandemic, when an airborne pathogen swept across continents with startling speed. It highlighted not just the fragility of public health systems, but the overlooked role of air quality and containment in public venues, travel modes, hospitality venues, and healthcare and research environments.

Hospitals, designed to heal, can inadvertently become sites of transmission when airborne contaminants—ranging from viruses to drug-resistant bacteria—linger in poorly ventilated areas or bypass outdated filtration systems. For patients with compromised immune systems, even a routine visit can evolve into a dangerous exposure.

Laboratories add another layer of complexity. Facilities working with infectious agents must operate under strict biosafety protocols, yet history has shown that lab-related viral accidents, whether due to human error or equipment failure, do occur. These incidents underscore the need for robust air handling systems and airtight containment procedures, especially in high-level biosafety labs.

Clean rooms, used across medical, pharmaceutical, and semiconductor industries, demonstrate how controlled environments can mitigate airborne risk. These spaces rely on meticulous air purification, pressure regulation, and contamination control to maintain sterility. From surgical prep to vaccine development, clean-rooms are the frontline defense against invisible intrusions.

The future of health infrastructure depends on treating air not just as a backdrop—but as a vector. Systems that monitor, filter, and control airflow are becoming as vital as the tools used for diagnosis and treatment. The goal is clear: safer environments where healing and discovery are not compromised by the very air we breathe and the ability to move thru our world without fear of exposure to our environment.

How can we defend ourselves against invisible threats?

The answer lies in creating environments that can be continuously filtered and sterilized—without disrupting the way we live and work. That’s exactly what the Modular Contaminate Capture and Sterilization Apparatus and Method delivers: a dynamic solution for safeguarding airspace in high-risk settings.

PRODUCT FEATURES & BENEFITS

Special features

In-room sterilization for occupied spaces

Offers smart modular retrofits for legacy HVAC systems

Mobile sterilization for emergency and field use

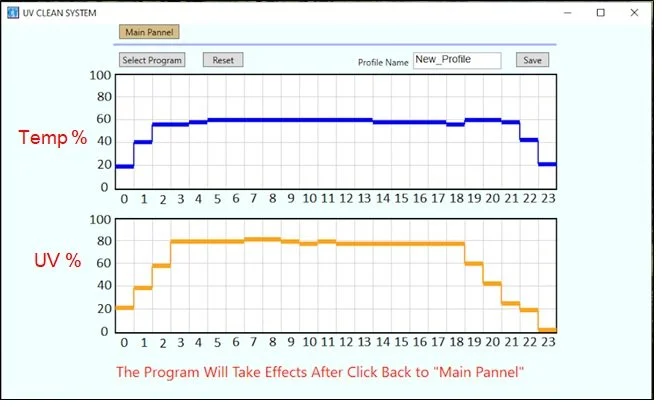

Programmable sterilization specific to a contaminate

Interchangeable treatment chambers

Movable baffles and dampers adjust airflow

Adaptable for clean-room grade sterilization for mid-tier labs

Programmable for a variety of contaminates

Ability to store contaminate-specific profiles in memory

Sensors in each chamber monitor treatment effectiveness

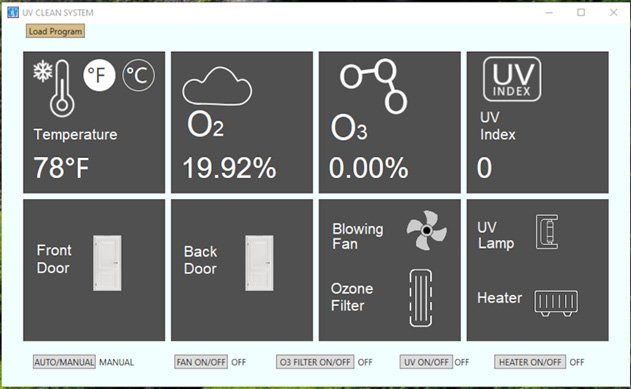

A processor receives sensor data and dynamically adjusts treatment

Accessible via touch screen or phone app

Portable – removable wheels

PRODUCT DETAILS

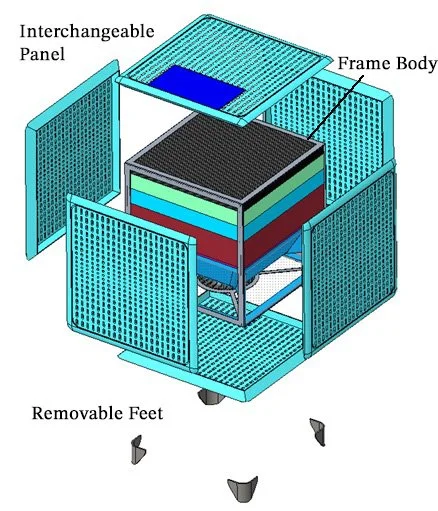

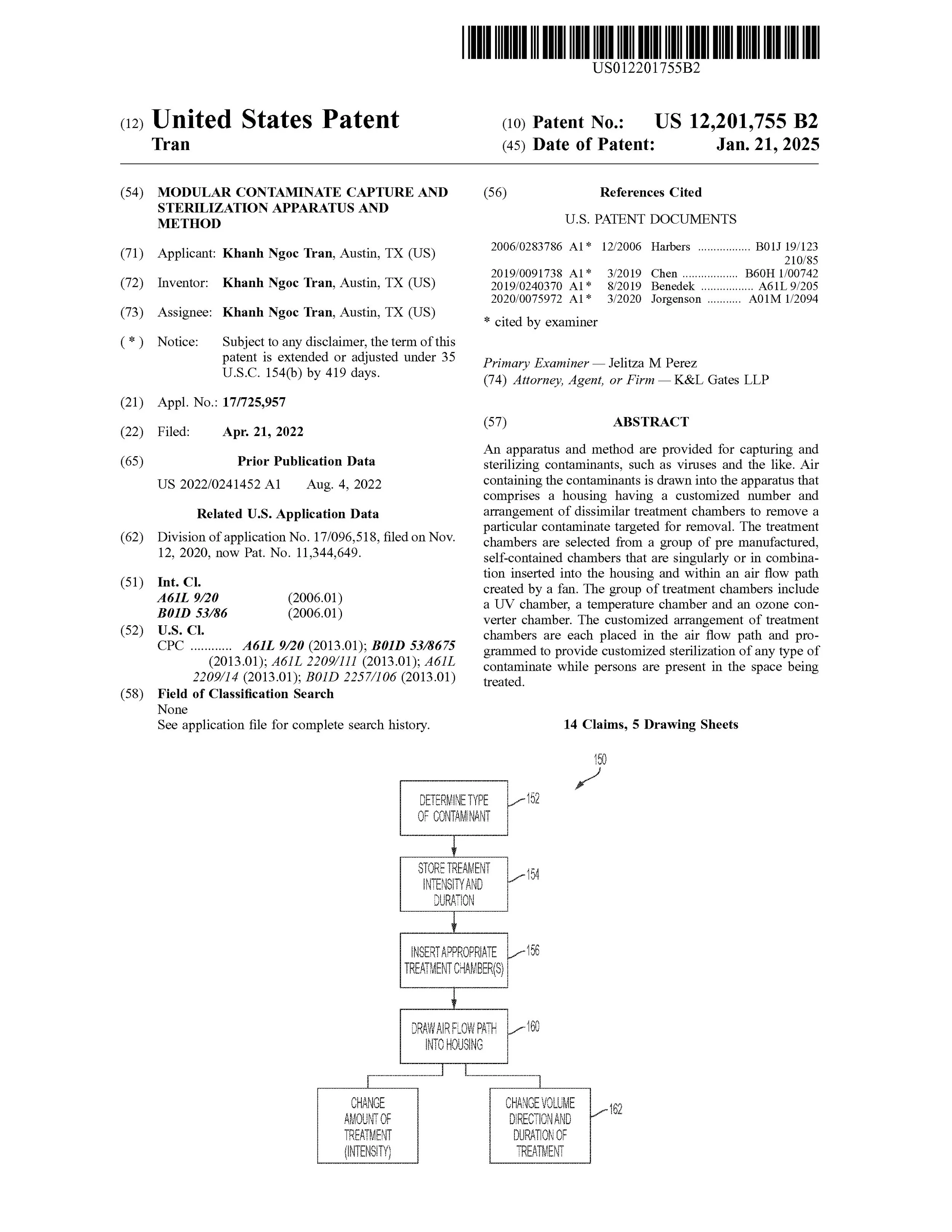

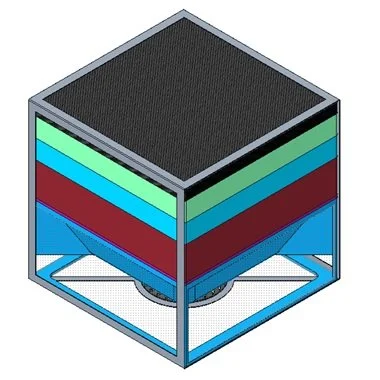

Our Modular Contaminate Capture and Sterilization Apparatus and Method operates with a distinct and modular design that sets a new standard for air purification systems.

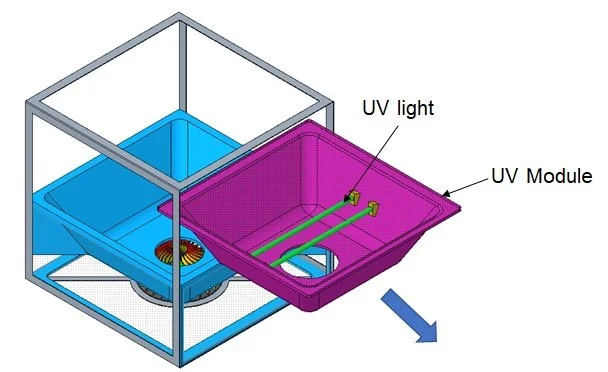

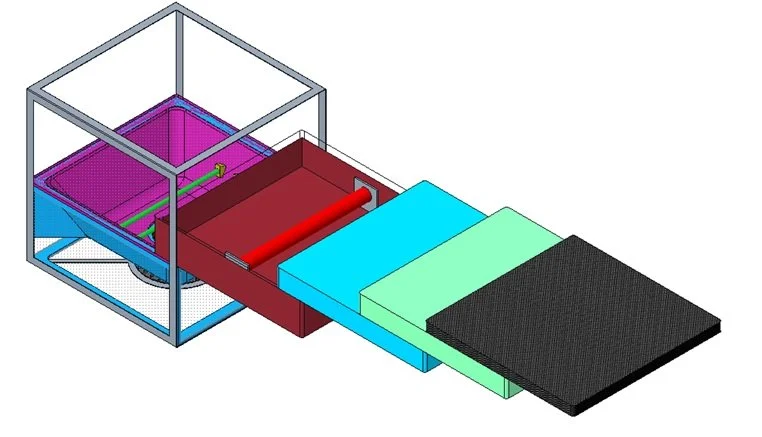

Ø Interchangeable Chamber System

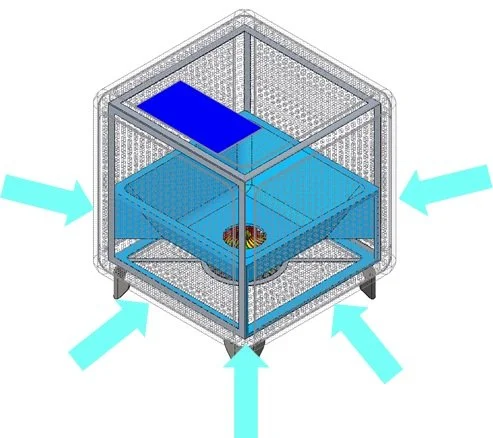

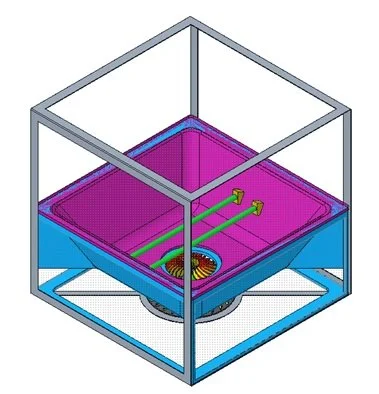

At its core is a customizable series of treatment chambers, each engineered for targeted sterilization:

· UV Chamber: Neutralizes pathogens using concentrated ultraviolet light

· Temperature Chamber: Applies thermal modulation to deactivate contaminants

· Ozone Converter Chamber: Transforms hazardous ozone into safe, breathable oxygen.

These chambers fit seamlessly into the housing and are positioned along the air stream for progressive, layered treatment.

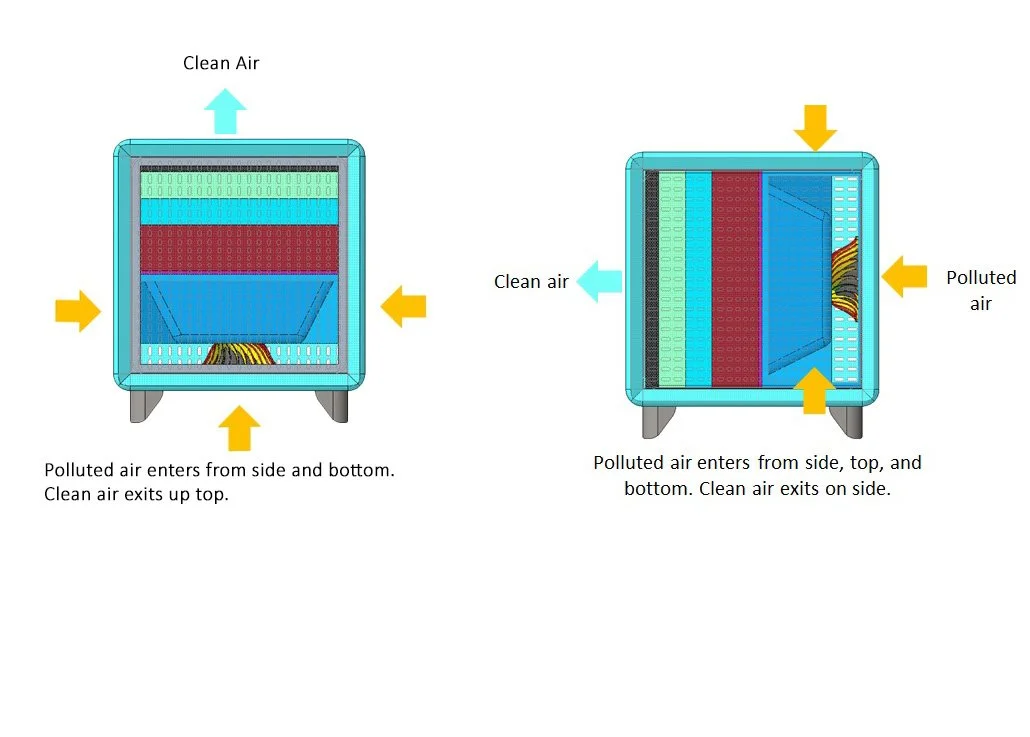

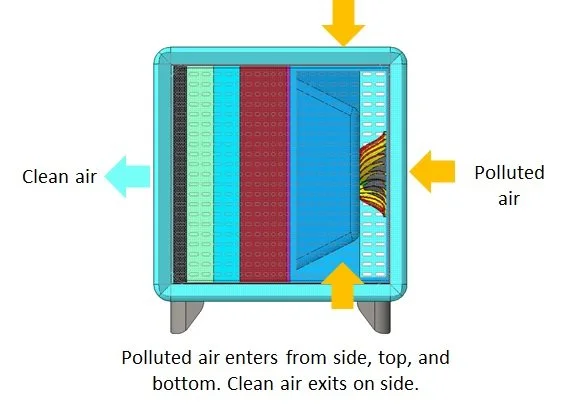

Ø Intelligent Airflow Management

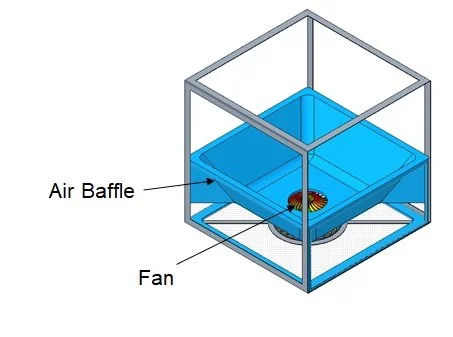

A powerful intake fan directs contaminated air into the system, where it is filtered through each chamber in a tailored, programmable sequence. Each chamber includes:

· Adjustable baffles to fine-tune air direction and flow

· Recirculating dampers that extend treatment duration for increased efficacy

Ø Real-Time Sensor Feedback

Embedded sensors in every module actively monitor and control performance:

· UV sensors gauge lamp output

· Temperature sensors regulate thermal conditions

· Airflow sensors track velocity and movement

A central processor collects this data to dynamically adjust treatment intensity, exposure time, and flow patterns for optimal results.

Ø Contaminant-Specific Programming

Our system can store and execute sterilization profiles based on contaminant type.

For example, in response to airborne viruses such as COVID-19:

· The UV chamber engages high-intensity irradiation

· The Temperature chamber adds heat-based deactivation

· The Ozone converter restores breathable conditions

This closed-loop control allows for agile response to emerging threats in any environment.

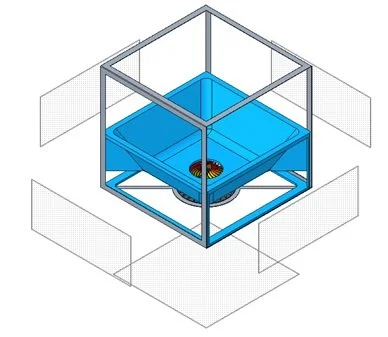

Ø Mobile, Occupant-Safe Deployment

With integrated wheels and a compact housing estimated at 12” x 18” x 11” and weighing an estimated 10 lbs, the unit is effortlessly deployable across rooms, buildings, and outdoor sites.

Most importantly, it operates safely while people are present—a distinct advantage over conventional systems that require vacated spaces.

Materials needed to produce the Modular Contaminate Capture and Sterilization Apparatus and Method:

Fan and fan motor

UV lamp

Sensors

Heating and cooling elements

HEPA filter

Metal housing and frame – steel or aluminum

Computer processor

Touch screen.

The Modular Contaminate Capture and Sterilization Apparatus and Method can elevate your product portfolio to new heights. We are seeking a long-term arrangement with a company to manufacture, market, and/or distribute this new technology based on the acquisition of the intellectual property rights . Contact us below

Contact Us

Our VP of Business Development, Amy Schleicher, is ready to answer any questions you may have.

Phone: 913-201-8025

Patent Information

Patent 11,344,649

Patent 12,201,755

Inventor Highlight

Mr. Khanh (Kelvin) Tran holds a BS in EE and Computer Science. With over 38 year of experience in design, programming, and manufacturing. One of his hobbies is watching TV programs such as the Military Channel, Technology Channel, and How It Works Channel. These programs facilitate his learning in many ways and help him come up with new product ideas.

Social Media

Follow us in real time! Stay connected.

“I know that our bodies were made to thrive only in pure air, and the scenes in which pure air is found...”