NitroWine

Sparkling wine has long been the beverage of celebration—defined by its crisp effervescence and bright acidity. From Champagne-inspired cellars in Napa to brunch tables nationwide, its sensory profile has remained remarkably consistent. Yet in a U.S. market valued at $9.09 billion and projected to grow steadily through 2030 (Statista), and a global market approaching $290 billion (Global Market Insights), the category is overdue for innovation—and primed for disruption. With over 79 million gallons consumed annually in the U.S. and average retail prices exceeding $8.50 per bottle, the scale is clear. What’s missing is differentiation.

Nitrogen-infused sparkling wine introduces a breakthrough at the intersection of tradition and beverage science. Historically used for preservation, nitrogen now plays a starring role as a co-carbonating agent—delivering a smoother mouthfeel, cascading pour, and creamy head that redefine the sparkling experience. Inspired by the commercial success of nitro cold brew and nitro beers, this patented process transforms not just the texture, but the emotional impact of the pour.

As American wineries compete for younger consumers and seek to stand out in a saturated premium segment, nitrogen-infused sparkling wine offers more than novelty. It offers brand identity, sensory storytelling, and defensible IP. For investors, it presents a first-mover opportunity in a category with scalable volume, premium pricing, and cross-vertical expansion potential.

The future of sparkling isn’t just fizzy—it’s frothy, immersive, and unforgettable. It is NitroWine.

Special Features

Dual-Gas Carbonation: Combines CO₂ (60–80%) and N₂ (20–40%) for a softer effervescence and frothy head.

Pressure Optimization: Maintains 35–50 psi, with 15–25 psi from CO₂ and the remainder from N₂, ensuring consistent texture and shelf stability.

Sensory Differentiation: Reduced acidity perception, and smoother finish compared to traditional sparkling wines.

Unmistakable Effervescence: is added to the drink, with the perception of creaminess

Nitrogen enhanced flavor notes: accentuating certain notes above others - a bitter tea can be smoothed out, and a more aromatic experience (more nose), it can improve wine flavors.

Eye catching foam and frothiness: while also enhancing taste with a more textured mouthful and aroma.

The pour is fun! Like a champagne pop pour! Then, while drinking, the consumer experiences a silky refreshing experience

PRODUCT FEATURES & BENEFITS

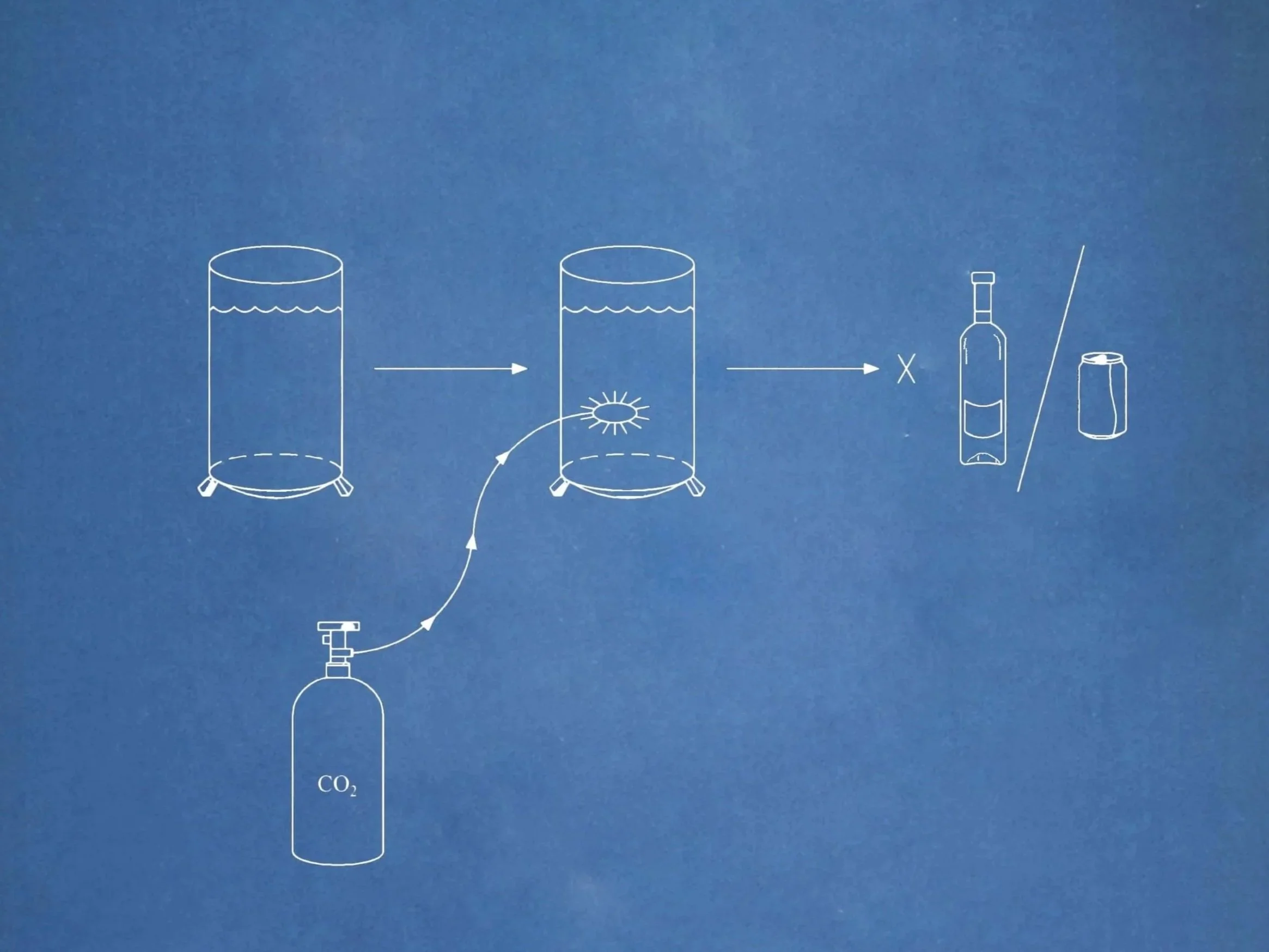

NitroWine is made by infusing nitrogen during batching and mixing, dosed during the filling process, or applied using special widgets inserted inside each container. Here is a breakdown:

PRODUCT DETAILS

Step 1: Base Wine Preparation

Input: Stabilized, filtered wine—typically white or rosé, selected for balance and clarity

Goal: Create a clean, neutral canvas optimized for gas infusion and flavor retention

Tools:

Multi-stage filtration system (removes particulates, yeast, and proteins)

Stainless steel wine tank with temperature control

This step ensures microbiological stability and consistent sensory performance. The wine must be free of residual fermentation activity to prevent unwanted gas interactions later.

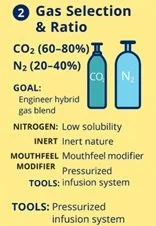

Step 2: Gas Selection & Ratio

Gases Used:

CO₂ (60–80%) – provides effervescence and sparkle

N₂ (20–40%) – adds creaminess, reduces acidity, and softens mouthfeel

Goal: Engineer a hybrid gas profile that delivers both visual drama and a velvety texture

Why Nitrogen:

Low solubility → forms cascading bubbles and a frothy head

Inert nature → preserves wine flavor without chemical interference

Mouthfeel modifier → creates a smoother, less acidic finish

The gas ratio can be tuned based on varietal, desired foam density, and target consumer experience (e.g., “draft latte” texture vs. champagne crispness).

Step 3: Infusion Process

Method:

Inline infusion – continuous flow through a pressurized gas chamber

Batch tank infusion – static wine held under pressure for controlled saturation

Pressure Range:

Total: 35–50 psi

CO₂: 15–25 psi

N₂: remainder (typically 10–20 psi)

Goal: Achieve stable carbonation and uniform nitrogen dispersion without over-saturation

Tools:

Dual-gas pressurized infusion system

Inline flow meters and pressure regulators

Precision is key—over-carbonation can lead to gushing, while under-infused nitrogen compromises texture. Real-time monitoring ensures consistency across batches.

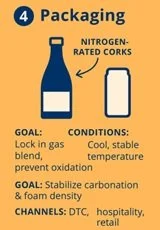

Step 4: Packaging

Containers:

· Glass bottles, aluminum cans, stainless steel kegs—all rated for high internal pressure

Closures:

Crown caps (for cans and kegs)

Nitrogen-rated corks or synthetic closures (for bottles)

Goal: Lock in the gas blend and prevent oxygen ingress that could flatten texture or oxidize flavor

Optional:

Nitrogen headspace purge to displace oxygen before sealing

Packaging must balance aesthetics with technical integrity. Transparent bottles may showcase bubble dynamics, while cans offer portability and freshness

Step 5: Storage & Distribution

Conditions:

Cool (45–55°F), stable temperature

Avoid vibration and light exposure

Channels:

Direct-to-consumer (DTC) e-commerce

Hospitality (bars, lounges, tasting rooms)

Retail (premium beverage shelves, experiential pop-ups)

Goal: Preserve gas integrity, texture, and shelf life across logistics chain

Step 6: Serving Experience

Pour

Dramatic cascade of fine bubbles

Creamy, latte-like head that settles slowly

Texture:

Silky mouthfeel

Lower perceived acidity

Enhanced fruit and floral notes due to nitrogen’s inert profile

Goal: Deliver a multisensory experience that differentiates from champagne and Prosecco.

Serve chilled in wide-mouth glassware to showcase foam and aroma. Ideal for “wow factor” pours in tasting rooms or influencer content.

Materials needed to produce the NitroWine:

. Wine

. CO₂ - carbon dioxide

. N₂ - nitrogen

. Packaging

. Cans

. Bottles

. Corks

The NitroWine can elevate your product portfolio to new heights. We are seeking a long-term arrangement with a company to manufacture, market, and/or distribute this new technology based on the acquisition of the intellectual property rights . Contact us below

Contact Us

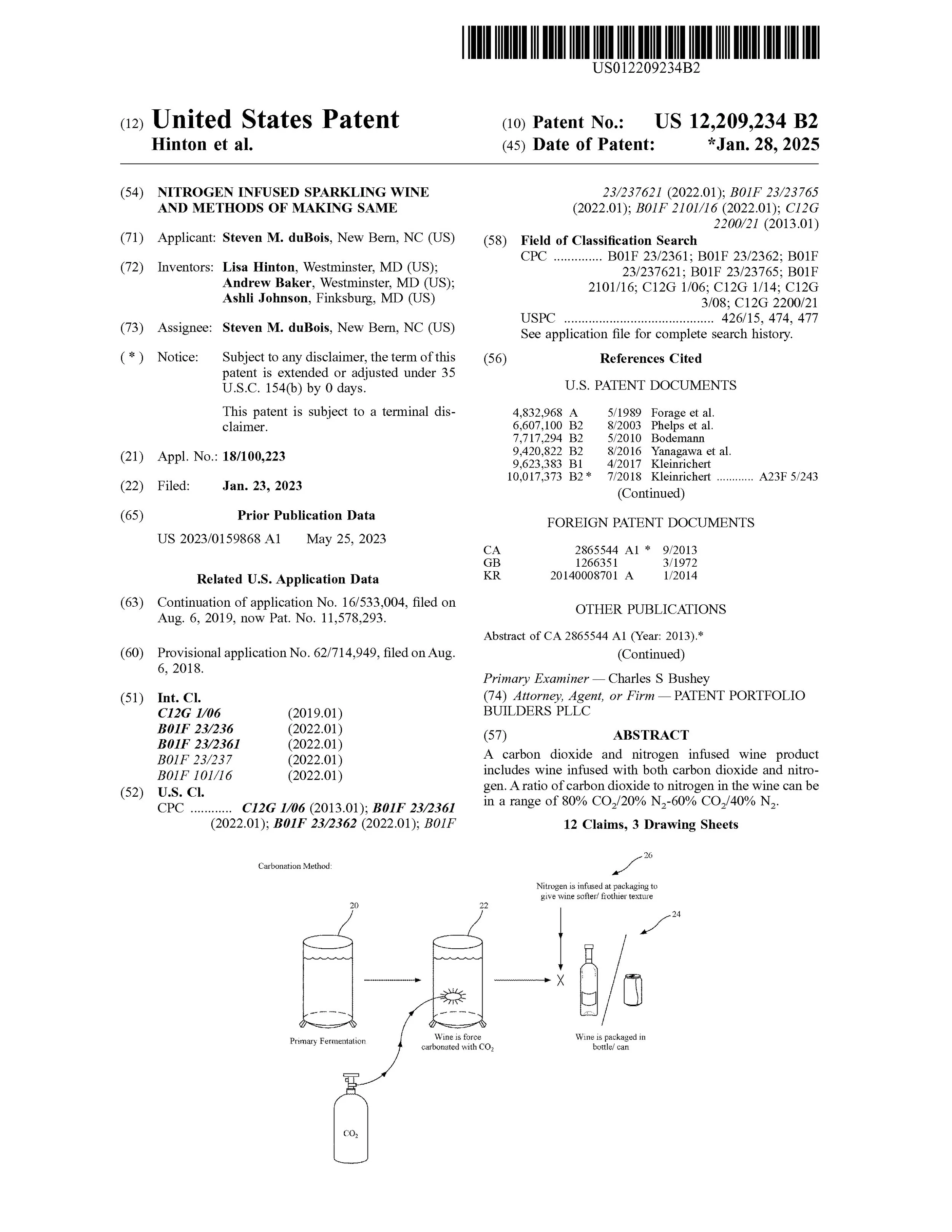

Patent Information

Patent

Inventor Highlight

Lisa Hinton, Andrew Baker, and Ashli Johnson hold United States Utility Patent No. 12,209,234 filed on January 23, 2023, and issued on January 28, 2025. This patent for the Nitrogen Infused Sparkling Wine and Methods of Making Same expires in 2043, commensurate with the filing date. This patent has 12 claims that protect the exclusive function of the NitroWine. They also own the United States Utility Patent No. 11,578,293 filed on August 6, 2019, and issued on February 14, 2023.

Social Media

Follow us in real time! Stay connected.

“There’s a way to do it better—find it”