Timlin Cycle™

For nearly two centuries, steam power has served as the backbone of industrial energy conversion. From the early steam engines of the 18th century to the widespread adoption of the Rankine cycle in modern turbines, thermal power systems have relied on water-based motive fluids and high-temperature heat sources to generate mechanical energy. While effective, these systems often struggle with complexity, cost, and inefficiency—especially when operating at lower temperatures.

Historically, the Carnot cycle defined the theoretical efficiency ceiling for thermal systems, but its practical implementation remains elusive. The Rankine cycle, developed by William Rankine before 1872, offered a more achievable framework—especially for steam turbines—but still depends on high-grade heat and water as the motive fluid.

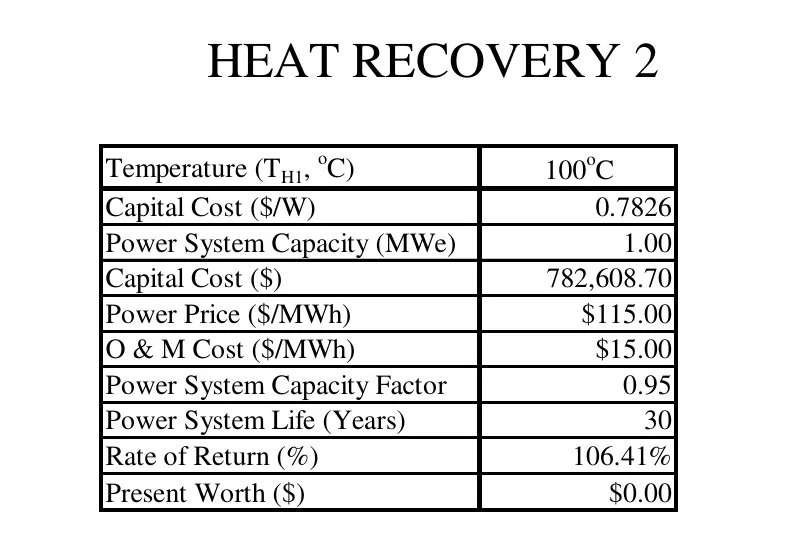

The Timlin Cycle™ introduces the first transformative alternative in 30 years: a novel thermal power cycle that delivers higher efficiency, lower cost, and simplified architecture compared to conventional steam, Kalina, and Organic Rankine Cycle (ORC) systems. The Timlin Cycle™ lays the foundation for future innovations in clean energy conversion and represents a next step in efficient processing at lower temperatures.

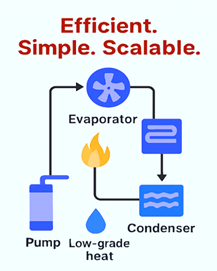

The Timlin Cycle™ converts heat into mechanical power by compressing a non-aqueous wet fluid, evaporating it under subcritical conditions, expanding it isentropically into a two-phase vapor-liquid mixture, and condensing it via direct-contact heat exchange. This approach eliminates the need for superheating, reduces back-pressure losses, and simplifies the system to just four core components: pump, evaporator, expander, and condenser.

The Timlin Cycle™ redefines the motive fluid paradigm by introducing wet binary motive fluids to operate effectively across a broad range of low-to-moderate heat source temperatures (≤100°C - ≥200°C), including ALL Wet Non-Aqueous Motive Fluids, comprising:

Pure substances (e.g., methanol)

Mixtures thereof, and

Azeotropes thereof

By expanding the fluid options and simplifying the system architecture, the Timlin Cycle™ opens the door to modular, scalable, and site-adaptable energy systems — Industrial Heat Recovery, Oil/Gas Co-Production, Geothermal, and Solar Thermal — where traditional steam-based systems are less viable.

PRODUCT FEATURES & BENEFITS

Special Features

Runs efficiently at ≤100°C - ≥200°C

Wet expansion – saturated or superheated vapor expands into a two-phase mixture, maximizing energy extraction

Flexible fluid selection – supports azeotropes and mixtures tailored to specific temperature ranges and resource types

Direct-contact condensation - enhances heat rejection and simplifies system design

Low-pressure condensation improves expander efficiency

Only 4 core components - pump, evaporator, expander, and condenser

Uses a liquid pump – replacing energy-intensive compressors, reducing parasitic losses

Uses simpler, smaller turbines

Omits expensive parts like superheaters and regenerators

Higher thermal efficiency - converts thermal power to mechanical/electrical power at +30% to +130% greater efficiency than similar ORC systems in the field today

Lower overall cost – implementation will be simpler and less expensive than similar Kalina and ORC systems: -33%

Scalable – from small systems (<5 MWe) to large systems (>50 MWe)

Retrofit – upgrading existing installations with fewer components

New construction – easy implementation

PRODUCT DETAILS

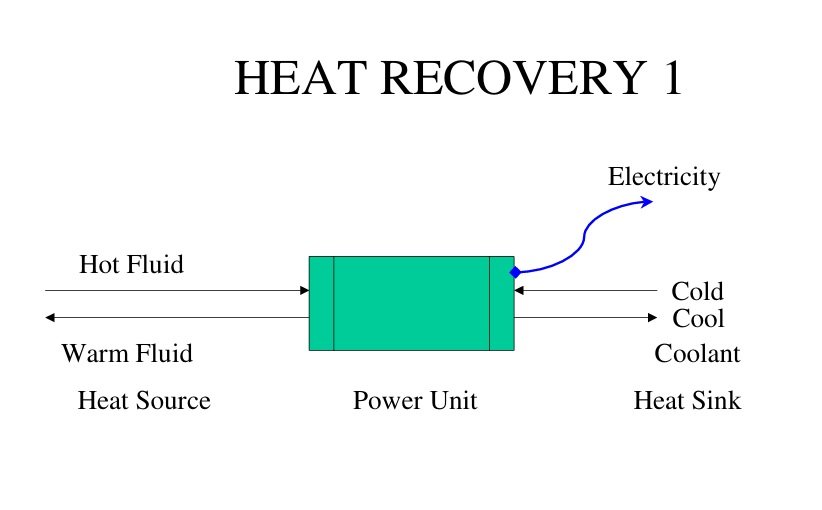

Most energy systems discard low-temperature heat as unusable waste. Traditional steam turbines demand high-grade heat, sidelining valuable sources like geothermal wells, industrial exhaust, and solar thermal collectors.

Now imagine a system designed to capture and convert that overlooked resource—efficiently, affordably, and without high temperature steam.

The Timlin Cycle™ opens new possibilities for:

Geothermal developers tapping moderate-temperature wells

Factories reclaiming waste heat from exhaust streams

Solar thermal arrays that harvest heat instead of light

Emergency relief teams deploying off-grid power in remote zones

Industrial sites operating far from centralized grids

It’s not just a new cycle—it’s a new category of energy access.

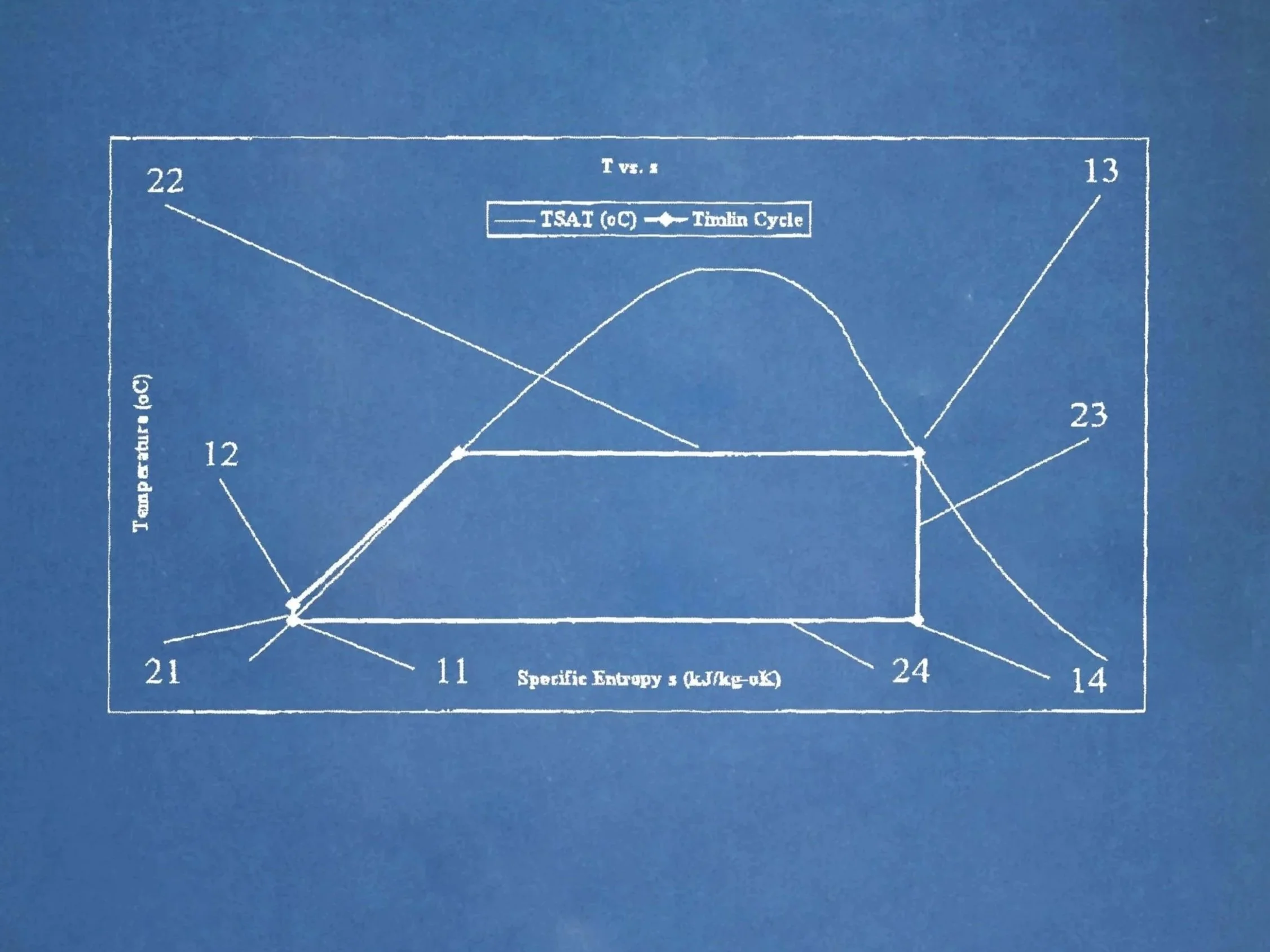

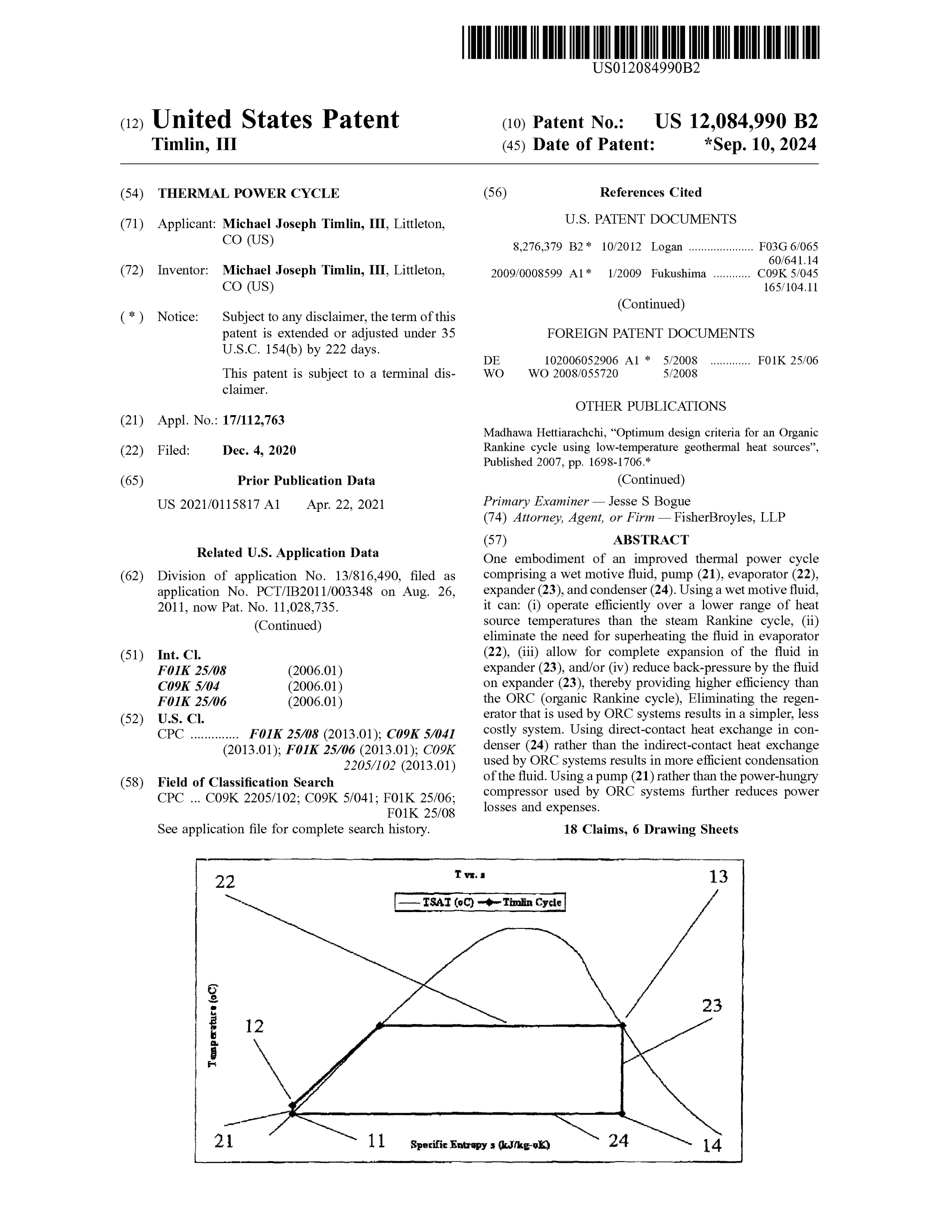

The Timlin Cycle™ consists of four core thermodynamic processes:

Isentropic compression of saturated liquid into subcooled liquid via a pump.

Isobaric heating of the subcooled liquid in an evaporator until it reaches saturated vapor.

Isentropic expansion of the saturated vapor through an expander, producing a two-phase vapor-liquid mixture.

Isobaric cooling of the two-phase mixture in a condenser, returning it to saturated liquid.

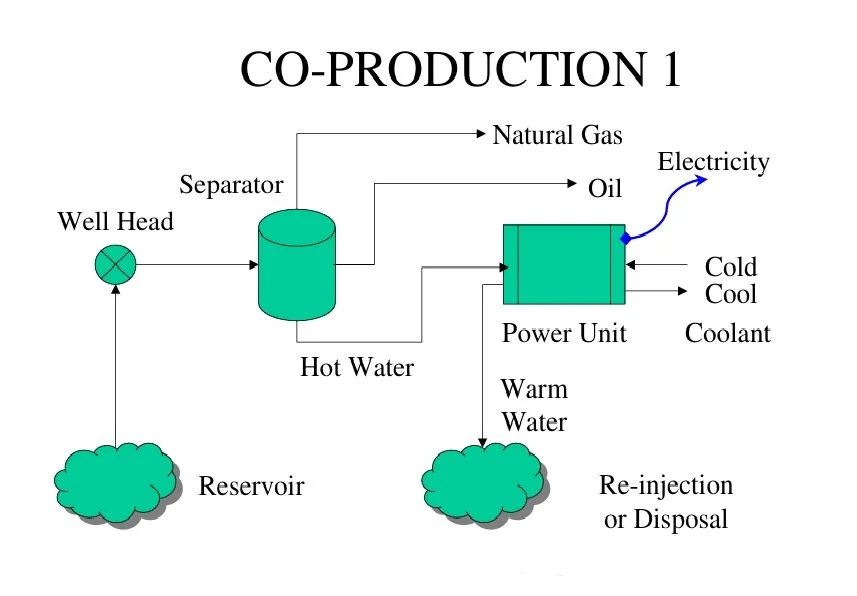

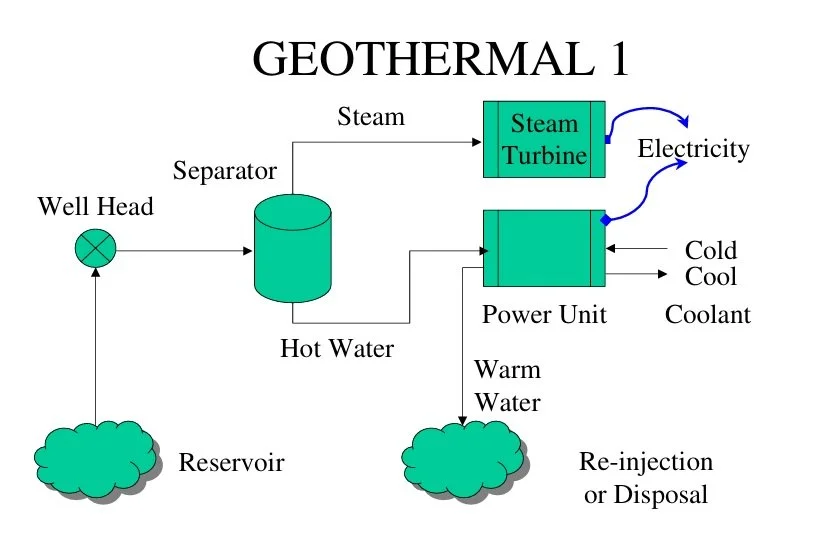

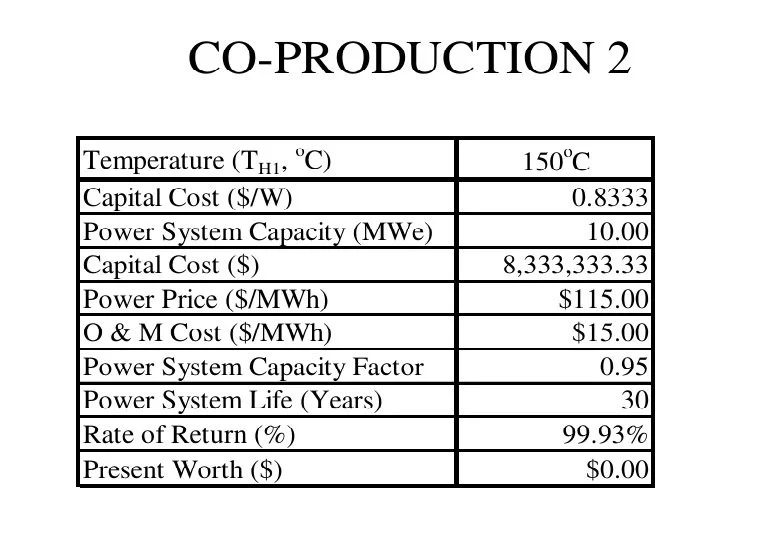

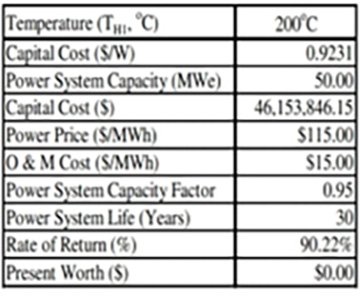

The Timlin Cycle™ targeted applications include, but are not limited to:

Heat recovery

Co-production

Geothermal

The Timlin Cycle™ also accommodates several advanced variations:

In a second option, the evaporator may heat the subcooled liquid beyond saturation to produce superheated vapor.

In a third option, the expander may handle superheated vapor, converting it into a two-phase mixture during expansion.

Additionally, option three may include a staged expansion:

Initial isentropic expansion of superheated vapor

Reheating to a drier vapor state

Followed by further isentropic expansion to a cooler, wetter condition at the expander’s exhaust

The Goal – Recover heat, to produce more power, at lower cost!

Materials needed to produce the Timlin Cycle™:

Wet binary motive fluid

Pump

Evaporator

Expander

Condenser

The Timlin Cycle can elevate your product portfolio to new heights. We are seeking a long-term arrangement with a company to manufacture, market, and/or distribute this new technology based on the acquisition of the intellectual property rights . Contact us below

Contact Us

Our VP of Business Development, Amy Schleicher, is ready to answer any questions you may have.

Phone: 913-201-8025

E-mail: Amy@bankonip.com

Patent Information

Patents

11,028,735

12,084,990

Inventor Highlight

Mr. Michael Joseph Timlin III holds United States Utility Patent No. 11,028,735 and also holds United States Utility Patent No. 12,084,990.These patents have claims that protect the exclusive function of the Timlin Cycle™.

Mike Timlin’s unique qualifications in this technology space are as follows:

Hertz Foundation (Doctoral) Fellow, Mechanical Engineering

Stanford (MSME), Thermosciences

Auckland (PGCert), Geothermal Energy Technology

USMA (BS), Applied Sciences and Engineering

Sole owner and inventor of the Timlin Cycle™

Social Media

Follow us in real time! Stay connected.

“There’s a way to do it better—find it”