Transport Vehicle with an Expandable Cargo Bay™

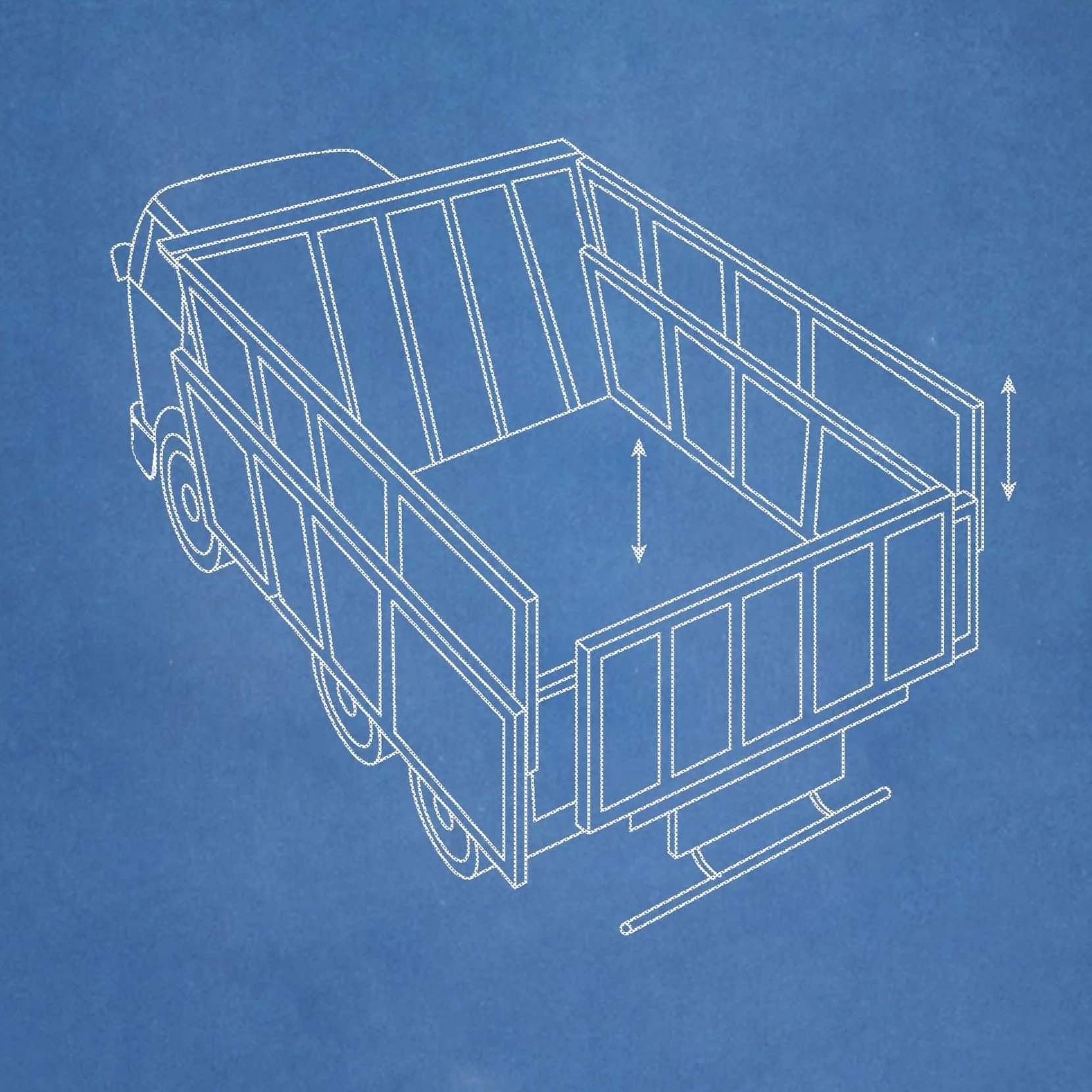

The Transport Vehicle with an Expandable Cargo Bay™ was developed to meet the demands of the cargo market head-on. Featuring a multi-axis expandable cargo bay that adjusts in height, width, and length, this product can transform its capacity to match nearly any load. Powered by hydraulic actuators with a centralized push-button control panel, it allows operators to expand or retract the cargo space in minutes. Its modular compartments and precision guide rail system provide secure, customizable configurations, while the galvanized steel-grade housing ensures long-term durability against rust and harsh conditions. Designed to be both scalable across truck classes and versatile for commercial and military use, the Transport Vehicle with an Expandable Cargo Bay™ reduces downtime, streamlines fleet operations, and even offers a design ideal for toy and model applications.

PRODUCT FEATURES & BENEFITS

Special features

Multi-axis expandable cargo bay that extends in height, width, and length for maximum load flexibility

Hydraulically powered actuators for smooth, rapid deployment and retraction under load

Centralized electronic control panel with push-button operation

Modular design with expandable and sub-expandable compartments for mixed cargo needs

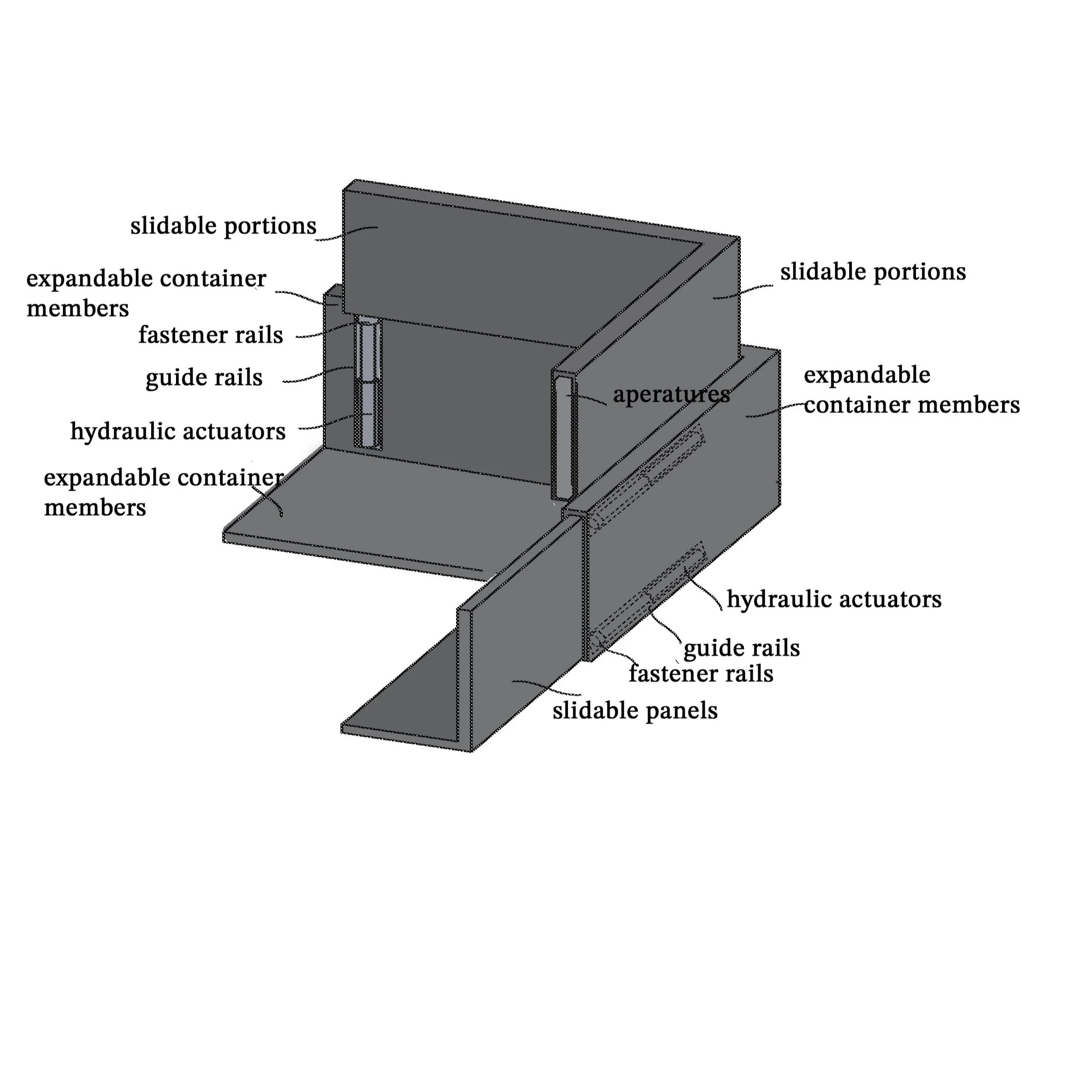

Precision guide rail and fastener system ensures secure locking and reliable alignment

Compact travel footprint with large, expanded capacity for road efficiency and site versatility

Scalable platform adaptable to light, medium, and heavy-duty truck chassis

Built with galvanized steel-grade housing to maximize durability and resist rust, corrosion, and harsh environmental conditions

Rapid reconfiguration reduces downtime between military missions or cargo delivery runs

Maintenance-friendly layout with easy access to actuators and guide systems

Built-in fastener rails for tie-downs, shelving, or mission-specific equipment integration

Easy to add weatherproofing and sealing options for sensitive or climate-controlled cargo

Reduces fleet size and operational costs by covering multiple payload profiles with one vehicle

Versatile platform engineered for both commercial logistics and military mission requirements

Able to minimize design to make the product ideal for toy, RC, and model manufacturers

PRODUCT DETAILS

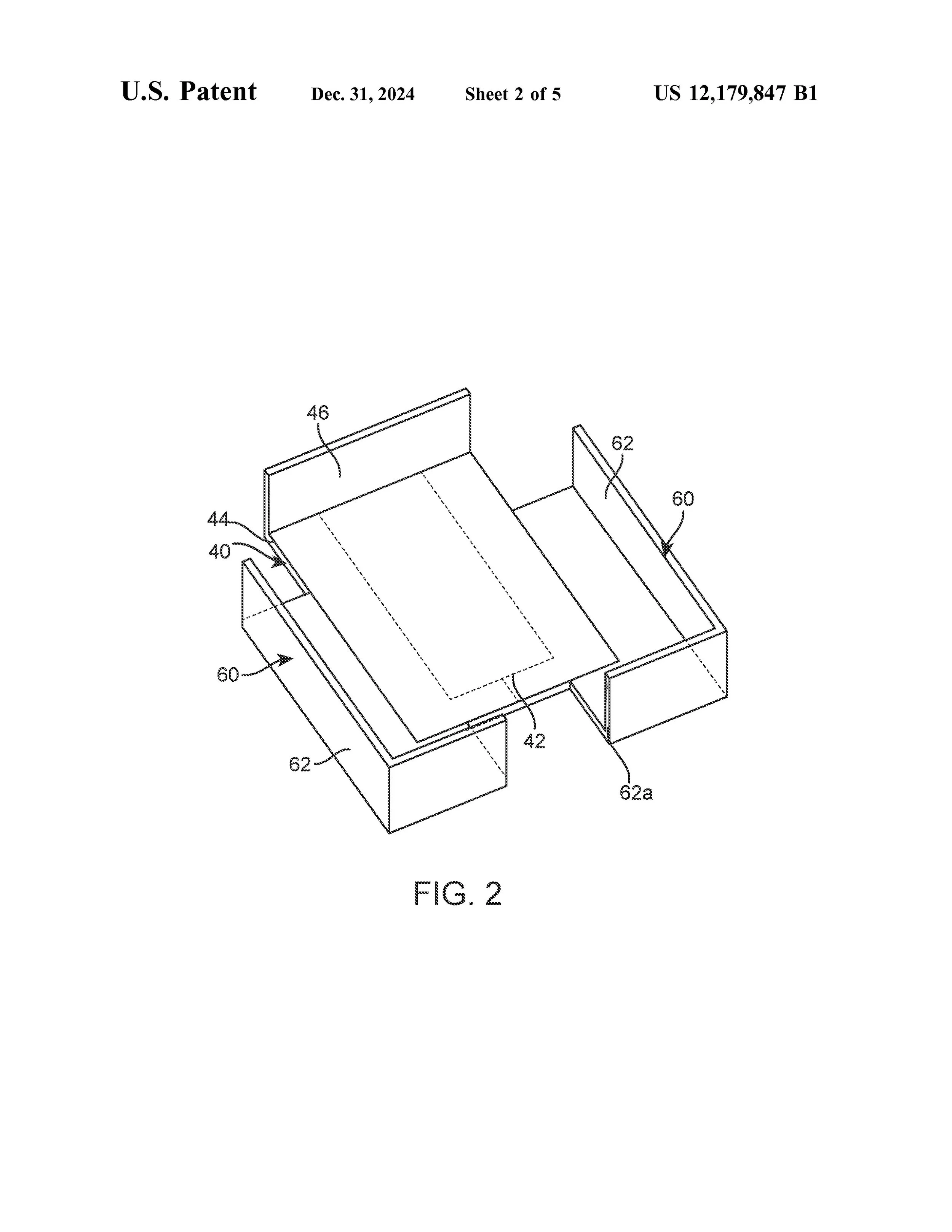

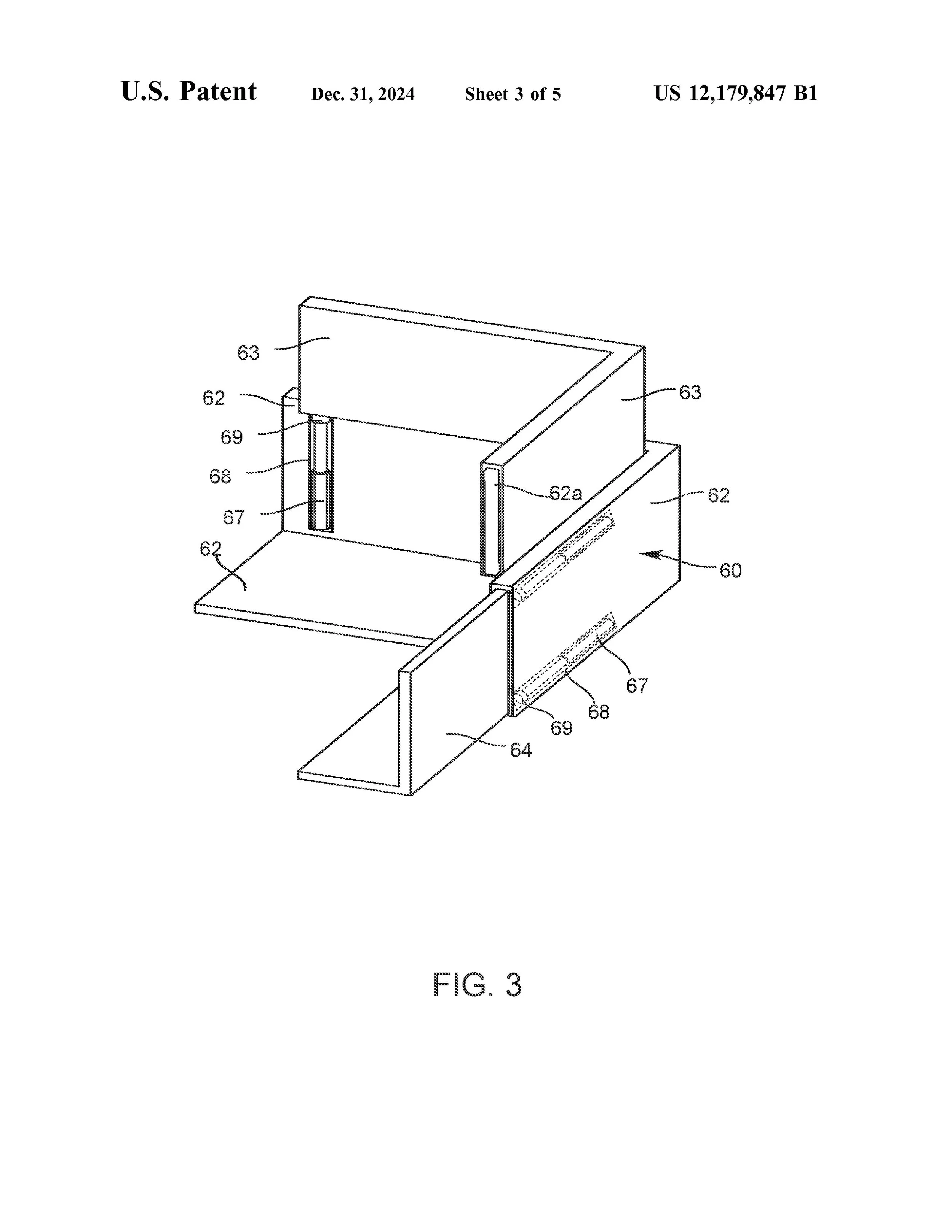

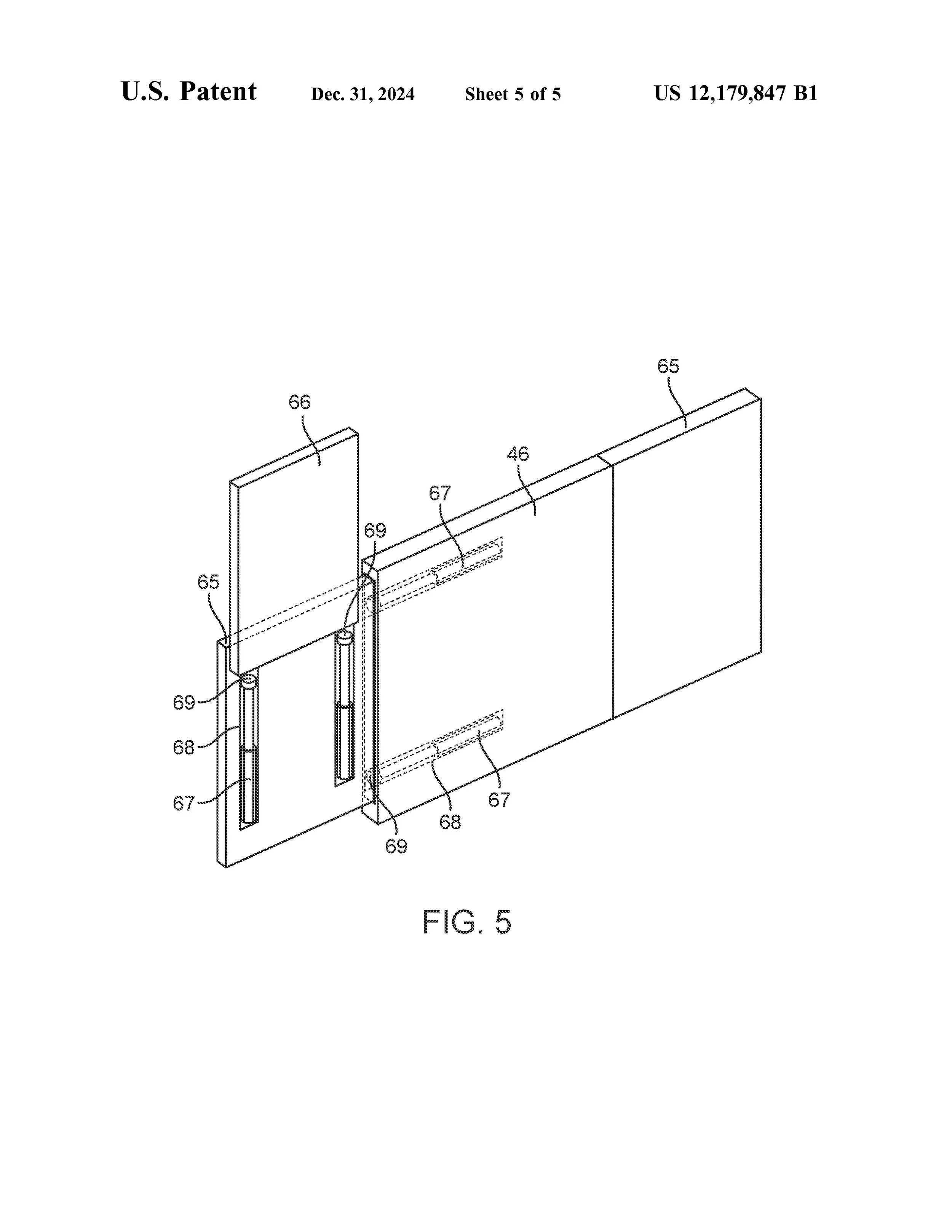

The Transport Vehicle with an Expandable Cargo Bay™ is engineered from the ground up as a rugged, mission-ready expandable cargo system. The core structure uses a galvanized steel-grade housing to maximize durability and resist rust, corrosion, and harsh environmental exposure. Precision guide rails and an integrated fastener-rail system form the mechanical backbone, keeping sliding panels square, aligned, and positively locked under vibration and heavy loads. This structural approach lets the Transport Vehicle with an Expandable Cargo Bay™ offer a compact travel footprint yet deliver a substantially larger usable bay when deployed. This makes this product ideal for operators who need high capacity on-site but low drag and profile on the road.

At the heart of the Transport Vehicle with an Expandable Cargo Bay’s™ motion is a hydraulically powered actuation suite paired with intelligent electronics. Telescoping hydraulic actuators handle the heavy lifting for height, width, and length expansion while digital valves and pressure sensing keep motions smooth and controlled. A centralized electronic control panel provides push-button operation and status readouts. The guide-rail geometry and fastener engagement are engineered for repeatable alignment so that every deployment results in consistent sealing, load-bearing capacity, and tie-down integrity

The Transport Vehicle with an Expandable Cargo Bay™ is simple and easy to operate through a system of hydraulic actuators connected to guide rails and slidable panels that allow the cargo bay to expand or contract along multiple axes. When activated, the actuators extend or retract the panels in coordination with the guide-rail system, ensuring proper alignment and secure engagement. Fastener rails and locking members hold the panels in place once extended, maintaining structural integrity under load and vibration. The expansion and retraction process is managed through an electronic control panel, which allows the operator to initiate and monitor movements. This design enables the cargo housing to transition between a compact form for travel and an expanded form for increased capacity with consistent and reliable operation.

This product’s modularity opens immediate practical use-cases. For commercial fleets, one example is a regional carrier that carries palletized goods one day with the expanded width and length, then retracts for densely packed urban multi-stop deliveries the next. This sizing flexibility reduces deadhead trips and the need for multiple vehicle types. In military logistics, the Transport Vehicle with an Expandable Cargo Bay™ can convert from a troop-transport footprint to a palletized resupply bay or a communications or equipment shelter in the field, with rapid reconfiguration between mission legs. Emergency response teams can deploy a mobile clinic or supply hub at disaster sites, using the built-in fastener rails for shelving, stretchers, or refrigeration modules. And because the mechanism is scalable and the design can be minimized accordingly, toy and model manufacturers can create functional replicas that demonstrate these engineering concepts at consumer scale.

This product’s modularity opens immediate practical use-cases. For commercial fleets, one example is a regional carrier that carries palletized goods one day with the expanded width and length, then retracts for densely packed urban multi-stop deliveries the next. This sizing flexibility reduces deadhead trips and the need for multiple vehicle types. In military logistics, the Transport Vehicle with an Expandable Cargo Bay™ can convert from a troop-transport footprint to a palletized resupply bay or a communications or equipment shelter in the field, with rapid reconfiguration between mission legs. Emergency response teams can deploy a mobile clinic or supply hub at disaster sites, using the built-in fastener rails for shelving, stretchers, or refrigeration modules. And because the mechanism is scalable and the design can be minimized accordingly, toy and model manufacturers can create functional replicas that demonstrate these engineering concepts at consumer scale.

Materials needed to produce the Transport Vehicle with an Expandable Cargo Bay™:

Galvanized steel or stainless steel

High-strength aluminum alloys

Reinforced composites or polymers

Hydraulic actuators and telescopic cylinders

Hydraulic pumps, valves, and hoses

Precision guide rails and fastener

Locking mechanisms and safety latches

Electronic control panel with buttons

Microcontrollers/PLC

Various sensors

Weatherproofing seals and gaskets

Paints, primers, and coatings

Fasteners

Bolts

Welds

Adhesives

The Transport Vehicle with an Expandable Cargo Bay™ can elevate your product portfolio to new heights. We are seeking a long-term arrangement with a company to manufacture, market, and/or distribute this new technology based on the acquisition of the intellectual property rights . Contact us below

Contact Us

Patent Information

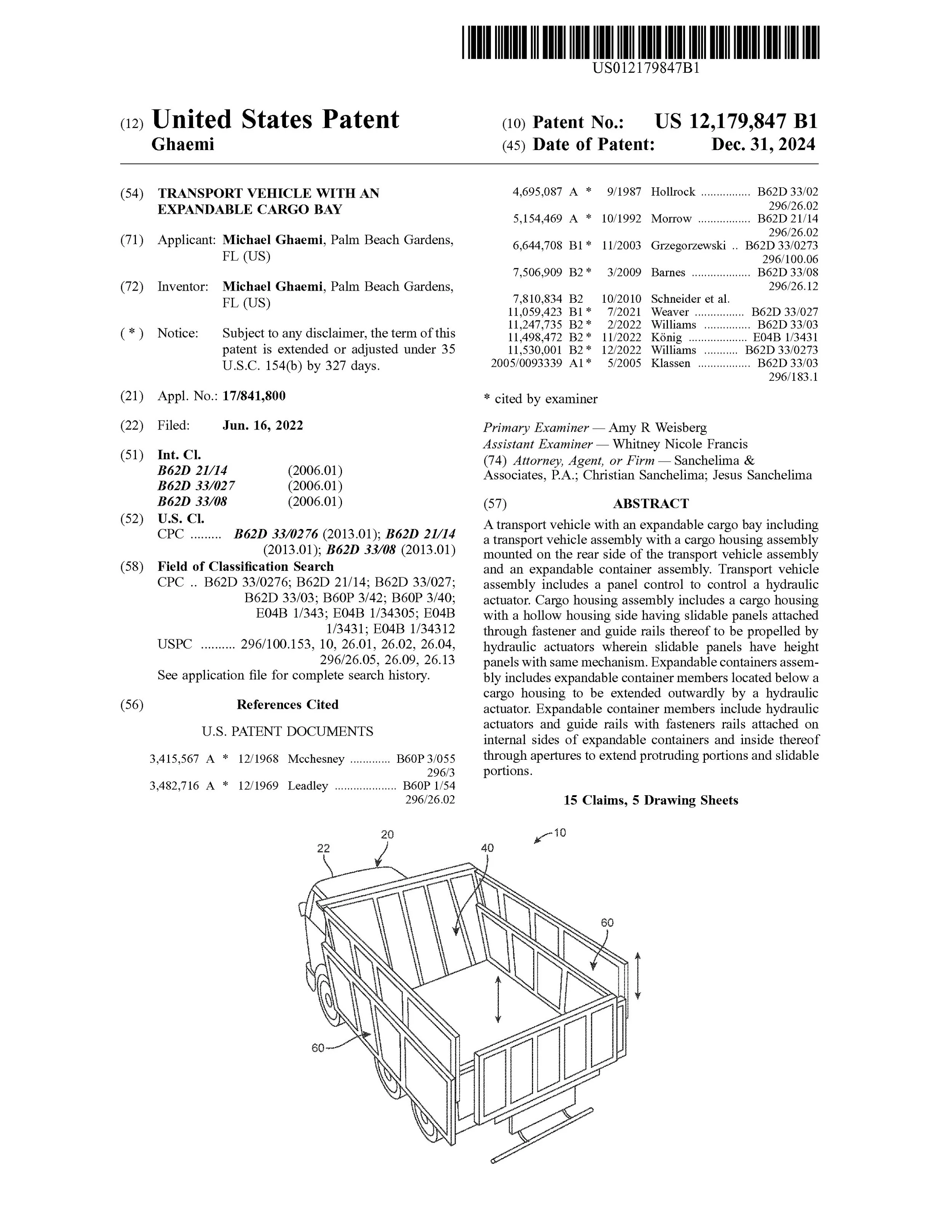

Patent 12,179,847

Inventor Highlight

Mr. Michael Ghaemi holds United States Utility Patent No. 12,179,847 filed on June 16th, 2022, and issued on December 31st, 2024. This patent for the Transport Vehicle with an Expandable Cargo Bay™ expires in 2042, commensurate with the filing date. This patent has 15 claims that protect the exclusive design and function of the Transport Vehicle with an Expandable Cargo Bay™.

Social Media

Follow us in real time! Stay connected.

“Safety first is safety always.” ”