Tree Peat

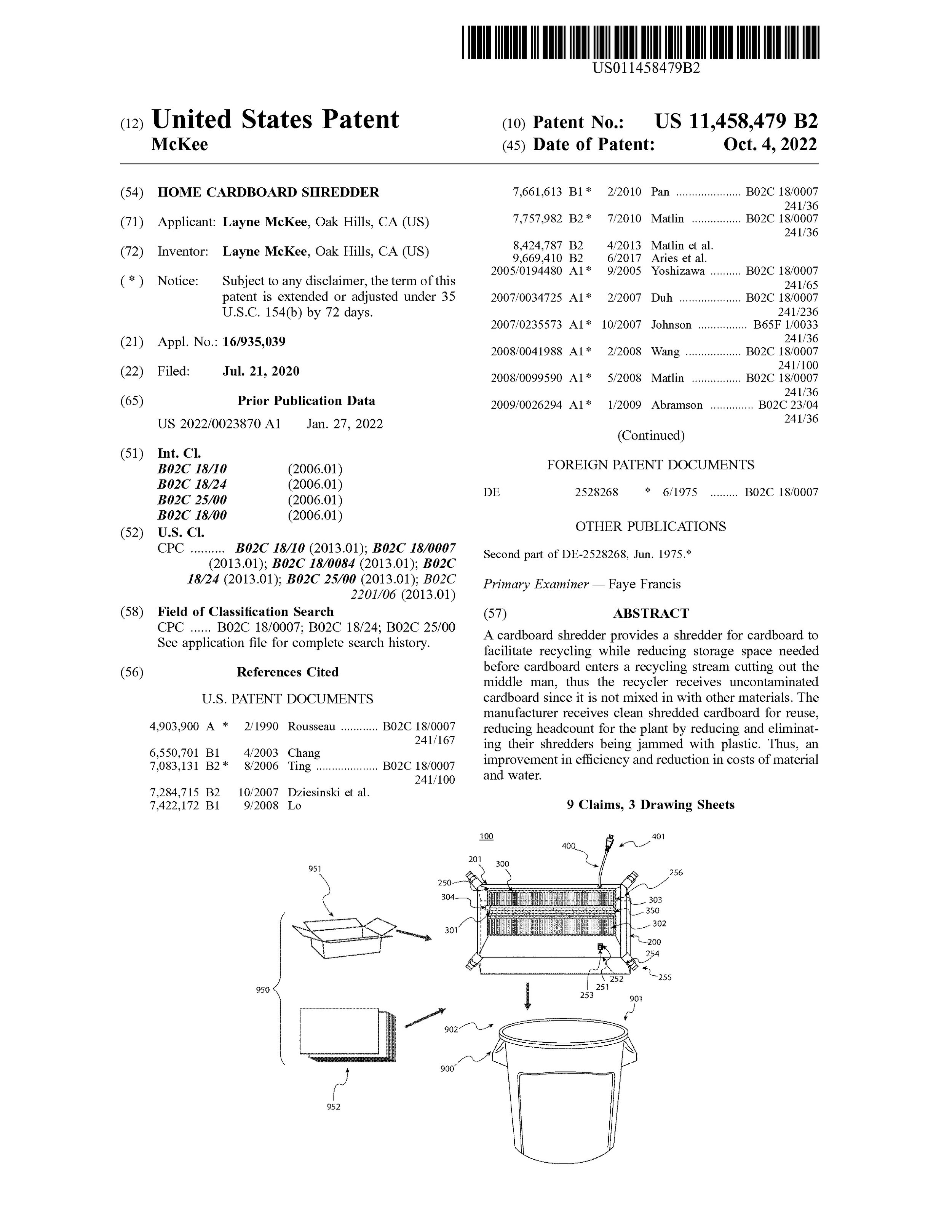

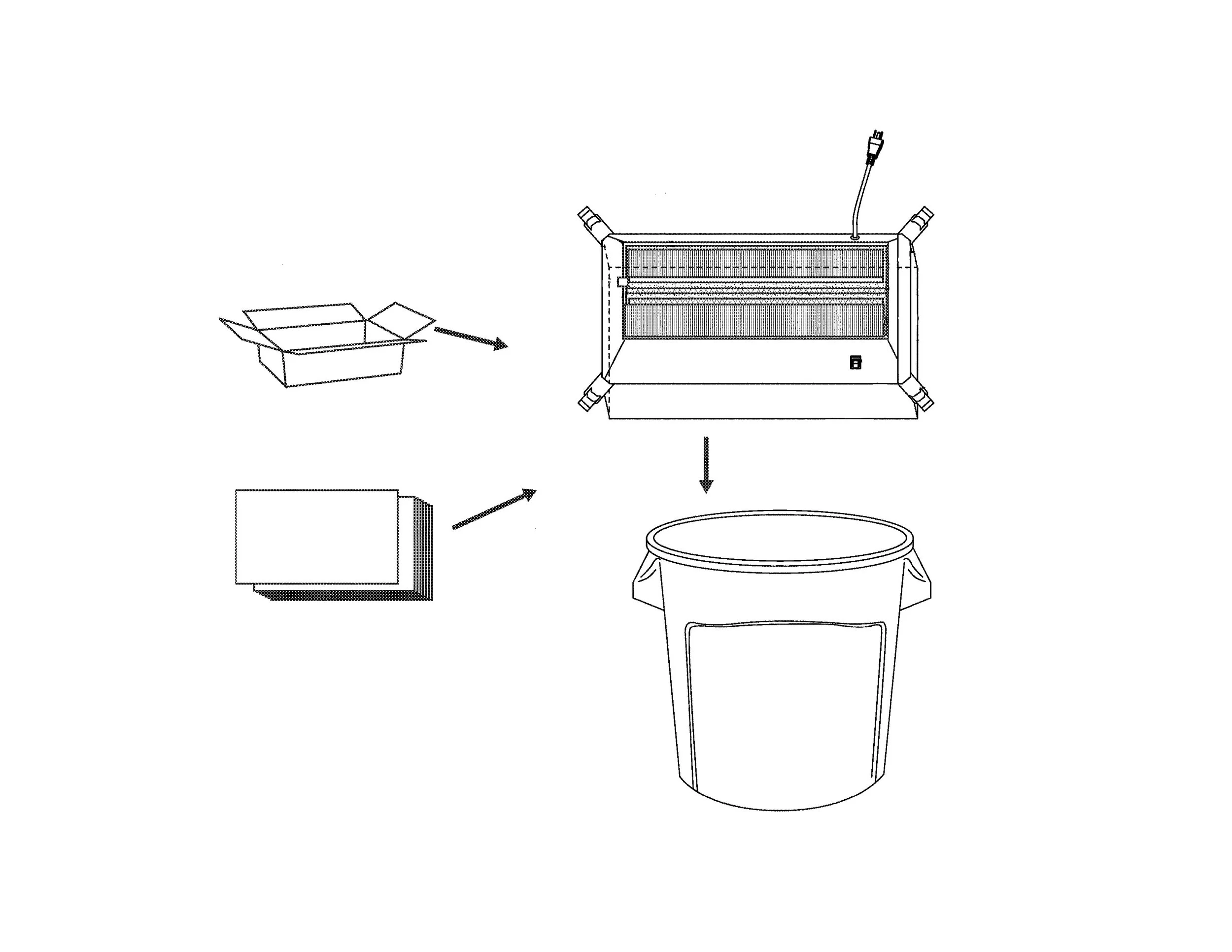

The Tree Peat is an innovative cardboard shredder designed to change the way cardboard is processed. By shredding cardboard at the source, Tree Peat minimizes storage requirements, eliminates the need for third-party handling, and ensures that recyclers receive uncontaminated material that is not mixed with other waste. This direct approach streamlines collection and enhances the overall quality of recovered fiber.

For manufacturers, Tree Peat delivers shredded cardboard that is cleaner and more consistent, preventing common issues such as plastic contamination that lead to jammed shredders and costly downtime. By reducing plant disruptions and eliminating inefficiencies, companies can operate with fewer staff dedicated to waste management, ultimately improving operational reliability and throughput.

The benefits extend beyond logistics and labor savings. With cleaner inputs and smoother recycling operations, manufacturers reduce water usage and material waste during processing. This translates to tangible cost savings, improved sustainability, and a more efficient circular economy model, making Tree Peat a strategic solution for businesses aiming to optimize recycling while lowering expenses.

PRODUCT FEATURES & BENEFITS

Special features

-Makes cardboard recycling easier

-Saves space within recycling bin

-Shredded cardboard usable for composting or sale

-Promotes a green image for retailers

-Exclusive rights are available

PRODUCT DETAILS

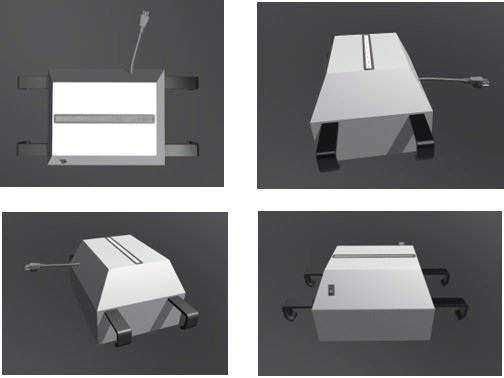

The Tree Peat is a purpose-built cardboard shredder designed for efficiency, safety, and durability in both residential and commercial settings. Built with a durable hard plastic or composite body, it is lightweight yet rugged enough for repeated daily use. The unit fits securely over standard household and commercial receptacles, shredding cardboard directly into containers to eliminate double handling and reduce storage space needs. Its metal cutting heads are engineered for strength and longevity, producing clean, uniform strips while requiring less power to operate, thanks to their wide, efficient design.

The Tree Peat uses an electric motor connected through a system of metal gears to deliver reliable torque and consistent shredding performance. A manual switch provides forward and reverse control, allowing jams to be cleared quickly, while integrated sensors enhance safety by detecting hand contact near the entry point and halting the blades instantly. Combined with a two-hand operation design, one hand on the switch and the other feeding cardboard, the unit minimizes the risk of injury while maintaining user-friendly functionality.

This combination of strong construction materials and practical engineering creates a shredder that resists wear while improving operational efficiency. By delivering uncontaminated, pre-shredded cardboard directly, Tree Peat reduces downtime from jams, lowers labor requirements, and saves water and materials in downstream processing.

Materials needed to produce the Tree Peat:

-Durable hard plastic or composite body

-Metal cutting heads

-Metal gears

-Electric motor

-Switch

-Sensors

The Tree Peat can elevate your product portfolio to new heights. We are seeking a long-term arrangement with a company to manufacture, market, and/or distribute this new technology based on the acquisition of the intellectual property rights . Contact us below

Contact Us

Our VP of Business Development, Amy Schleicher, is ready to answer any questions you may have.

Phone: 913-201-8025

E-mail: Amy@bankonip.com

Patent Information

Patent 11,458,479

Inventor Highlight

Layne McKee places his family above all else. Together with his wife, he has raised four remarkable children, each on a strong path toward building their own careers or completing their education. A hands-on entrepreneur, Layne owns and operates a diesel service business specializing in big rig trucks, with a fleet of mobile units serving clients throughout Southern California. Traveling across the region, he takes pride in maintaining and repairing trucks and trailers that keep the transportation industry moving.

Driven by a love of working with his hands, Layne enjoys building and creating, carrying a lifelong dream from fourth grade of calling himself an inventor. Beyond his professional life, he dedicates significant time to volunteering at his church, a commitment he embraces with enthusiasm, enjoying the camaraderie and shared purpose of working alongside wonderful people

Social Media

Follow us in real time! Stay connected.

“Recycling, packaging, businesses are changing all of those things because that’s what consumers want. ”